Float Level Sensors with Magnetic Reed Switches for Continuous Level Measurement.

Float level sensor (float switch) is one type continuous level sensor for industrial level measurement. Float level sensor has a magnetic float that rises and falls as liquid level changes. The percentage of the liquid level, 4 ~ 20mA current and liquid level value, can be displayed on site. Applications like: water tank, fuel tank, level measurement and level control. Vertical, horizontal, and side mounted, all can be satisfied.

Please feel free to contact us for Techinical Support, or Request a quote for float level sensors (customization available).

Description of SI-U01 Float Level Sensor

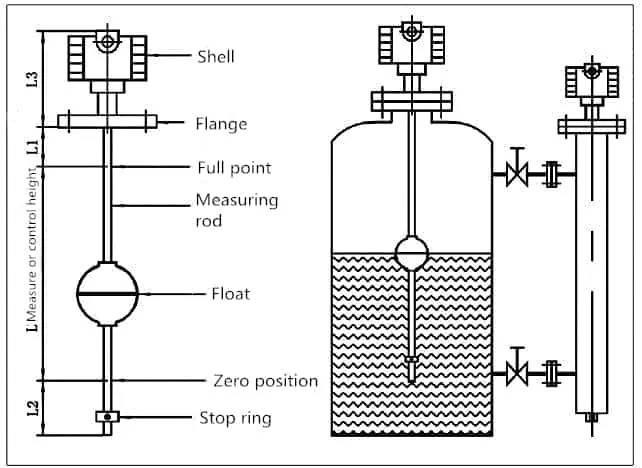

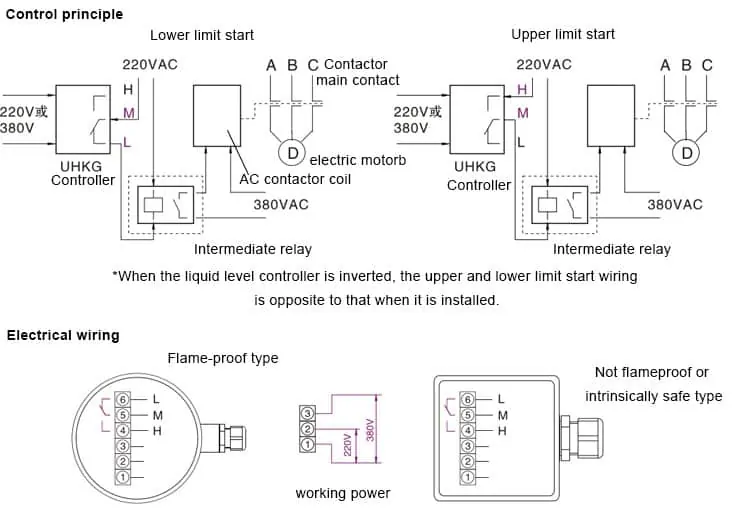

SI-U01 float level meter is composed of three parts: magnetic float, sensor and transmitter. When the magnetic float changes with the liquid level, it floats up and down along the duct. The magnetic steel inside the float attracts the reed switch at the corresponding position in the sensor. So that the total resistance (or voltage) of the sensor changes. The changed resistance (or voltage) signal is converted into a current signal of 4-20mA and output. And the upper and lower limit alarms can be set on the display to achieve the position control of the liquid level.

SI-U01 floating ball liquid level gauge consists of a liquid level sensor and an intelligent HART board (current converter). The floating ball and the liquid level change synchronously, and the reed switch is controlled to open and close. This makes the resistance in the sensor change linearly. The change of resistance is converted by the converter into 4 ~ 20mA standard current signal or superimposed HART digital signal output.

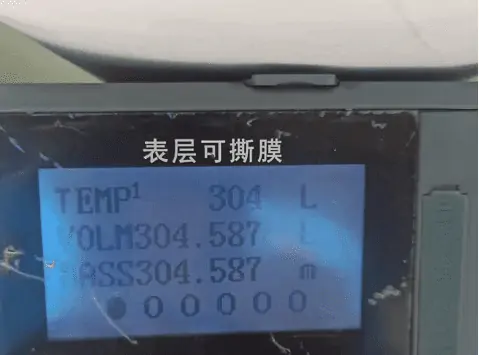

Float level sensor can also be used with paperless recorder.

Features of SI-U01 Continuous Float Level Sensor

- Intelligent electronic components are composed of a motherboard and an LCD screen;

- You can adjust the range and zero point by pressing the button on the spot;

- It can use HART communicator or microcomputer to communicate with this smart meter on both sides without interrupting the output signal.

- It is suitable for explosion-proof or inconvenient installation and disassembly of the meter. Instrument measurement, process parameters, equipment configuration, calibration, diagnostic information HART protocol access or change;

- Two-way communication with the host in the distributed control system using the HART protocol;

- With EEPROM, no data is lost due to power failure.

- Simple working principle, wide applicability, safe, convenient and maintenance-free

- Realize the connection measurement of the liquid level without being affected by the physical and chemical properties of the measured medium. Such as: temperature, pressure, conductivity, dielectric constant, etc.

- The use of different materials can achieve the measurement of highly corrosive media

- It can be used to measure the interface of two different density liquids.

- Good repeatability.

Specifications of SI-U01 Float Level Sensor

| Max insert depth | L=6m(>6m customize) |

| Max control scope | L-120mm |

| Min control scope | 50mm(<50mm customize) |

| Medium density | >0.5g/cm3 |

| Working pressure | PN2.5~ PN160(Max pressure PN320) |

| Working temperature | -40~80 °C, -40~120 °C, -40~150 °C (250°C customize ) |

| Float diameter | D28~D120(depending on pressure and density) |

| Installation type | Flange: DN40~DN150 Flange standard: HG/T20592~2009 (pressure>PN25, Flange>DN125) G2” thread Other method (consulting) |

| Maximum switch frequency | <1×105 |

| Inaccuracy | ±8±2mm |

| Working power supply | 220VAC/380VAC |

| Max voltage of switch | <250VAC |

| Max current of switch | 5A |

| Installation angle | < ±25° |

| Wiring box | M20×1.5 female thread |

| IP grade | IP65 |

| Explosion-proof grade | Exd II CT6Gb |

Float Level Sensor Operating Principle

Float level meter is an instrument for measuring liquid level. It is widely used in the field of liquid measurement. Many industries will choose to use it for measurement equipment. Such as the petroleum, chemical, and pharmaceutical industries.

Float level sensor is designed and produced based on the principle of buoyancy and static magnetic field. The position of a floating ball with a magnet (floating ball for short) in the measured medium is affected by buoyancy.

The change of the liquid level causes the position of the magnetic float to change. The role of the magnet and sensor (reed switch) in the floating ball changes the number of components (such as fixed resistance) connected in series to the circuit.

Thereby changing the electrical quantity of the instrument circuit system. That is, changes in the position of the magnetic float cause changes in the electrical quantity. The change of the electrical quantity is detected to reflect the liquid level in the container.

The float level sensor is installed on the top of the container through a connection flange. The float ball floats on the liquid surface according to the principle of discharging the liquid volume phase and so on.

When the liquid level of the container changes, the float ball also moves up and down. The reed switch of the ball level gauge is magnetically attracted to change the position of the liquid level into an electrical signal.

The actual position of the liquid is displayed digitally by the display instrument. The floating ball level gauge can achieve long-range detection and control of the liquid level.

Applications of SI-U01 Float Level Sensor

Float level sensors provide reliable readings in a range of operating environments.

Float level sensor can be widely used for continuous measurement of the liquid level (boundary level): High temperature. High pressure. Viscous, dirty media. Asphalt, wax-containing oil products and flammable, explosive, corrosive media.

Float level sensor can be used for industrial level measurement and control of various liquid tanks. Such as: Petroleum, chemical raw material storage. Industrial processes, biochemicals, medicine, food and beverage. Tank farm management and underground storage at gas stations.

The float level sensor is also suitable for dam water level, reservoir water level monitoring and sewage treatment, etc.

Of course, for different applications, you can choose different materials.

Such as:

Plastic materials PP and PVDF, suitable for strong acid and alkali places;

The metal material is SUS304 / 316L, which is suitable for high temperature 200 ℃ and high pressure 64kg/cm2.

Float level sensor Advantages and Disadvantages

Advantages

- Long life span, stable and reliable operation, easy installation, almost no maintenance

- None influence of measured medium in physical and chemical state. Eg: medium electrical conductivity, dielectric constants, foam, pressure, temperature, evaporation, boiling, bubbling effect etc, .

- Choose appropriate material can be used in a variety of bad media environment with densities ≥ 0.5G/CC ;

- Interface measurement with two media of different density control;

- Wide range of application. Pressures from vacuum to PN160 (special up to PN320), temperature -40~+150 ° c

- Design, explosion-proof, suitable for explosive environments;

- Controller can be used to control the upper and lower liquid level.

Disadvantages

- Low accuracy.

- The installation position is limited by the shape of the container.

- Most float level gauges are not suitable for corrosive or hazardous liquid media.

Float level sensor for water tank & fuel tank

In water treatment, the water tank float level switch is directly related to the safety and reliability of the entire process.

In a process, there are different types such as intermediate water tank, backwash water tank, produced water tank and waste liquid tank.

The sizes of these boxes are different. The volume of the produced water and the original water tank may be larger. In these water tanks, the water tank float level switch is used for related control.

Different level switches will have different actions. However, it is not necessary to have several level switches in a large water tank.

In the water tank, there are high and low level switches. The high level switch can detect whether the water tank is full. If it is full, the water production will stop. The low level switch is used to detect the water tank Is the water sufficient? If it is not enough, no more water can be sent out.

Water tank float level switch is a working condition word. If it is a large water tank, other level gauges can also be used to solve it. Like radar level gauges, ultrasonic level gauges, etc.

Of course, our float level sensor can also be used to measure and control the level of the fuel tank.

If it is used in an oil tank, special conditions such as the type of oil and corrosiveness need to be considered.

If you need to measure the level of the fuel tank. Please contact Sino-Inst sales engineers, we will provide you with suitable products and quotations based on your actual measurement situation.

Float Level Sensor for tank liquid volume monitoring

Our Float level sensors can output liquid level signals, such as 4-20mA signal, 0-10V signal, RS485 and so on.

However, the float level transmitter alone cannot calculate the liquid volume of tanks of different sizes. It’s too complicated. A separate recorder is required to calculate it.

Therefore, the digital display volume meter can collect, display and convert the liquid level of various regular and irregular tanks in the industrial field into the corresponding tank volume. It is suitable for monitoring, controlling and collecting various process parameters.

Read more about: Water Level Monitoring Sensor/System for Sewage-Wastewater

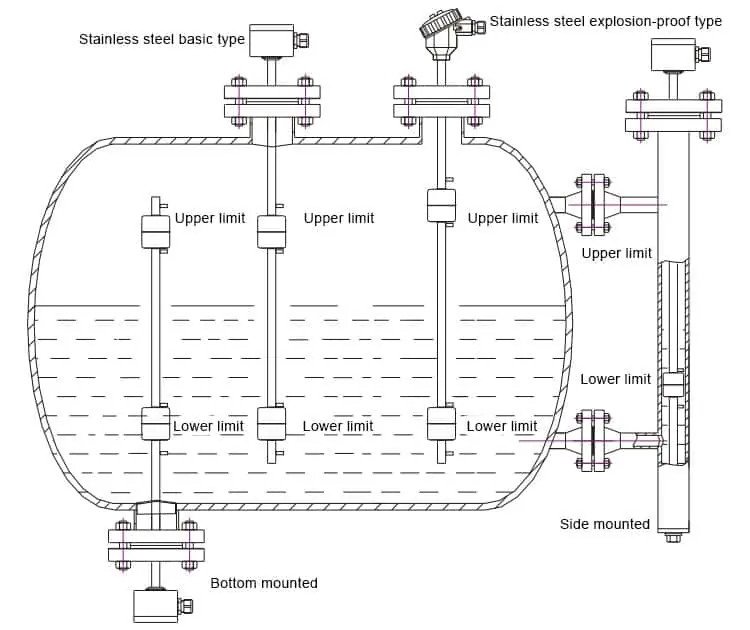

SI-U01 Float Leve Sensor Installation

The main float level sensor installation methods are:

Top mounted; Bottom mounted; Side mounted

SI-U01 Float level sensor installation instructions:

- The measured medium should not contain ferromagnetic impurities.

- In order to prevent the floating ball from falling off or hitting the sealing tube at high speed during transportation, which will cause the measuring tape to come out.

- The meter should be fixed to the bottom of the sealed tube with a clamp and the magnetic steel on top of the sealed tube before the instrument leaves the factory.

- Before installing and using, the user should remove the clamp. Raise the floating ball to the top of the sealing tube. And then slowly move the floating ball down, and the needle should be rotated accordingly.

- The indicator of the meter is pointer type, the indicator numbers are arranged in the direction of gel needles during full-scale measurement, and the indicators are arranged in the counter-clockwise direction during emptyness measurement.

- The instrument is equipped with a mounting flange when it leaves the factory. The user should have a pipeline flange.

- The installation position of the instrument is generally selected at half of the measuring range.

Float level sensor price

The float level sensor is a fully customized product. Different measurement needs will cause price changes. So before determining the price of the float level sensor, we need to confirm:

1.Junction box style

- Connection method

- Probe diameter

- Float distance

- Probe length

- Material selection

Sino-Inst is float level sensor manufacturer. On the premise of ensuring product quality, we will offer you the best price.

Frequently Asked Questions

If you cannot find an answer to your question in our Float Level Sensor, you can always contact us and we will be with you shortly.

Technical Support

Many people may confuse the float level sensor with the magnetostrictive level sensor. Because they look alike. But the actual working principle is different.

Sino-Ins is a manufacturer of Float Level Sensor. We provide more than 20 types of Float Level Sensors.

Float Level Sensor uses a magnetic floating ball as a measuring element. Through magnetic coupling, the internal resistance of the sensor changes linearly. The resistance change is converted into a 4~20mA standard current signal by an intelligent converter.

Float Level Sensor on-site liquid crystal display can display the percentage of liquid level, 4~20mA current and liquid level value on site. The remote supply control room can realize automatic detection, control and recording of liquid level.

Float Level Sensors can be widely used in the continuous measurement of high temperature, high pressure, viscous, dirty media, oil products such as asphalt, wax, and liquid levels (interfaces) of flammable, explosive, corrosive and other media.

Float Level Sensors can be used for liquid level industrial measurement and control of various liquid tanks such as petroleum, chemical raw material storage, industrial process, biochemical, pharmaceutical, food and beverage, tank farm management and underground storage of gas stations.

Float Level Sensors are also suitable for dam water level, reservoir water level monitoring and sewage treatment, etc.

Sino-Inst’s Float Level Sensors, made in China, have good quality, with better prices. Our Float Level Sensors are widely used in China, India, Pakistan, USA and other countries.

Sino-Inst’s entire team is well trained, so we can ensure that each customer’s needs are met. If you need any help with your product requirements, whether it is a Float Level Sensors, level sensors, or other equipment, please give us a call .

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.