Radar level sensor is the perfect choice for non-contact liquid level measurement. Suitable for sewage level measurement; low volatile acid and alkali level measurement; slurry level measurement.

Radar level sensor antenna emits and narrow microwave pulse. This pulse propagates in space at the speed of light. When it encounters the surface of the measured medium, part of its energy is reflected back and received by the same antenna. The time interval between the transmitted pulse and the received pulse is proportional to the distance from the antenna to the surface of the measured medium. The 6GHz intelligent series radar level gauge is suitable for non-contact continuous measurement of the level of liquid, slurry, granular material and block material. Applicable In the occasions where temperature and pressure change greatly, inert gas and volatilization exist.

Sino-Inst offers a variety of Radar Level Sensors for industrial level measurement. If you have any questions, please contact our sales engineers.

Features of SIRD-801 Radar Level Sensor

- The hardware system uses advanced microprocessors and embedded system processing software. The signal algorithm processing integrates advanced Echo-capture signal processing technology. This makes the product applicable to various complex industrial plant conditions.

- The “empty tank pretreatment” technology enables the instrument to correctly identify effective echoes and obtain correct measurement results even in the presence of multiple false echo interference.

- Not affected by various complicated working conditions. Such as strong surface fluctuations, foam, moisture and dust interference.

Specifications of SIRD-801 Radar Level Sensor

| Applicable medium: | liquid, slightly corrosive liquid |

| Application: | Sewage level measurement; Low volatile acid-base level measurement; Slurry level measurement |

| Explosion-proof certification: | Exia IIC T6 Ga/ Exd IIC T6 Gb |

| Measuring range: | 20m |

| Antenna: | Rod antenna (PP/PTFE) |

| Frequency: | 6 GHz |

| Process temperature: | (-40~130)℃ |

| Measurement accuracy: | ±10mm |

| Process pressure: | (-0.1~0.3)MPa |

| Signal output: | (4~20)mA/HART |

| On-site display: | four LCD programmable |

| Power supply: | two-wire system (DC24V) four-wire system (DC24V/AC220V) |

| Repeatability: | ± 1mm |

| Housing: | aluminum single cavity/aluminum double cavity/plastic/stainless steel single cavity |

| Process connection: | flange (optional)/thread |

Radar Level Sensor’s Applications

- Power plants: coal piles, raw coal bins, fuel bins, reservoirs, waste gas purification tanks, bin pumps, ash storage, etc.

- Oilfield: crude oil or product oil storage tanks, three-phase separators, sedimentation tanks, sewage tanks (pools), drilling mud tanks, etc.

- Petrochemical: distillation tower, concentration tank, liquefied gas tank, ammonia tank, steam drum, oil refinery tank, asphalt tank, etc.

- Chemical industry: distillation tower, raw material and intermediate silo, reaction tank, ammonia tank, toxic liquid tank, solid silo, separator, etc.

- Metallurgy: ore silo, ore crusher, raw material silo, auxiliary silo, blast furnace, alumina powder silo, electrolytic cell buffer tank, etc.

- Cement: stone silos, raw meal silos, cement silos, coal powder silos, slag storage silos, etc.

- Water and water treatment: reservoirs, sewage tanks, water treatment tanks, sedimentation tanks, digestion towers, etc.

- Papermaking: raw material warehouse, storage tower, drying drum, etc.

- Others: food, pharmaceuticals, environmental protection, shipbuilding, etc.

Extended reading: Radar Level Meter for Corrosive Liquids

Radar Level Sensor Working Principle

A low-frequency radar level meter is a 6GHz radar level measurement product. It uses an advanced microprocessor. The low-frequency radar has a long emission wavelength, and when encountering obstacles, it can cause diffraction to bypass the obstacles. Then, through optimized echo processing technology, false echo processing technology, and software digital processing technology, the true level is calculated.

The antenna types and process connections are diverse, which can be applied to various working conditions and application schemes. There are more unique application schemes for temperature, pressure and small dielectric constant. At the same time, it integrates HART communication technology and a modular digital display module. When the product is in application, the debugging scheme is diverse and the debugging is simple.

Antenna system to launch and microwave receiving energy is very low, very short pulse. Radar waves travel with the speed of light. The running time can be through the electronic components are converted into a signal. Measurement of this special time extension method can realize stable, accurate in a very short period of time.

Even if the condition is very complex, the presence of false echo, with the latest micro-processing technology and debugging software also can analyze the level echo accurately.

Microwave antenna to receive the reflected pulse and transmitted to the electronic circuit.

A microprocessor to signal to process, to identify the micropulse generated on the material surface echo.

Echo recognition is completed by the pulse system, the accuracy can reach millimeter level.

From the material surface distance between D and T pulse is proportional to the time travel:

D=C×T/2

Where C is the speed of light

Because of the air tank is a known distance E, L:

L=E-D

By setting the empty tank height E (= zero), the full height of F (= full scale), and some application parameters.

Application parameters automatically make the instrument measure the environment. 4 – 20mA with the corresponding output.

Extended reading: Radar Liquid Level Sensor|Corrosive, steam, volatile liquids

Radar Level Sensor Advantages and Disadvantages

Let’s analyze its advantages first:

- The radar level gauge adopts an integrated design. It is mainly composed of electronic components and antennas. No moving parts. There is no mechanical wear. There are very few failures in use and long service life.

- The electromagnetic wave emitted by the radar level gauge can pass through the vacuum without a transmission medium. It is not affected by the atmosphere, steam, and volatilized fog in the tank.

- The radar level gauge can be used for almost all liquid level measurement.

- Adopt non-contact measurement. It is not affected by the density and concentration of the liquid in the tank.

- Large measuring range. The maximum measuring range can reach 0~35m. It can be used for high temperature and high pressure liquid level measurement.

- Key components such as antennas are made of high-quality materials. It has strong corrosion resistance and can adapt to very corrosive environments.

- Rich functions, with false wave learning function. Enter the actual liquid level of the liquid surface, and the software can automatically identify the false echoes from the liquid surface to the antenna and eliminate the interference of these waves.

- The parameter setting is convenient, and it can be set with the simple operation keys on the level gauge. It can also be modified with a handheld communicator.

The main disadvantages are as follows:

- Determine the height of the measured storage medium tank during calibration. And after empty calibration, the output of zero and full scale is set to 4mA for empty tank zero point and 20mA for full tank (maximum range).

- Some volatile organic matter in the measuring medium will crystallize on the horn or antenna of the radar level gauge. They need to be inspected and cleaned regularly.

- Interference wave influence. In daily maintenance, you can use a PC (with VEGA Visual Operating software) to remotely observe the reflected wave curve. For possible interference waves, the level gauge can be used to identify false waves. Remove the influence of these interference reflection waves to ensure accurate measurement.

Extended reading: Drop Antenna Radar Tank Level Sensor

Featured Radar Water Level Sensors

High frequency and low frequency Radar Level Sensor

The microwave frequency used by the microwave level meter has three frequency bands: C band (5.8~6.3GHz), X band (9~10.5GHz), K band (24~26GHz).

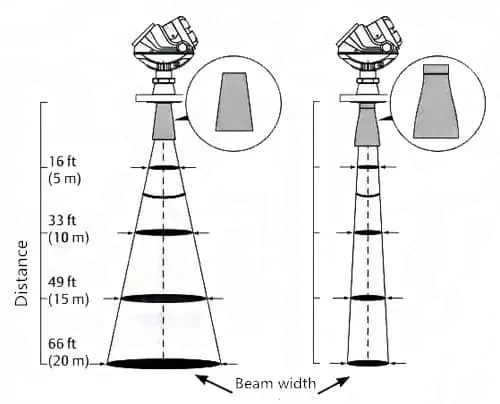

The microwave in level measurement is generally directional emission. The beam angle is usually used to quantitatively express the directivity of microwave transmission and reception. The beam angle is related to the antenna type and also to the microwave frequency (wavelength) used.

For the antenna of the same size, a level gauge with a wavelength of 1.2cm and a frequency of 26 GHZ has 6 times higher gain than a level gauge with a wavelength of 3cm and a frequency of 10 GHZ. The antenna gain is a parameter indicating the concentration of radiation from a directional antenna.

The receiving signal diagrams of different frequencies (26/10/6 GHZ), the same antenna, dielectric constant and distance increase are as follows:

Extended reading: Radar Non Contact Water Level Sensor

The total beam width of the radar level gauge is inversely proportional to the frequency of the device. Therefore, for an antenna of the same diameter, if the frequency of the radar level gauge is increased, the beam width will be lower than that of a lower frequency device. The narrow beam minimizes the influence of the nozzle, tank wall and interference.

At the same time, the measurement range of the radar level gauge is also affected by factors such as frequency, antenna size, dielectric constant of the liquid, and process conditions.

The application difference between high frequency and low frequency of radar level sensor.

Low-frequency radar level gauges are preferred when measuring steam, foam, and condensate. In most other applications, high-frequency radar level gauges are preferred for ease of installation.

- The lower frequency reduces the sensitivity to steam, foam and antenna contamination. The low-frequency radar has a wider wave speed angle. It can better deal with the problems of steam, dust, condensation, pollution and turbulent surfaces.

- The higher frequency minimizes the impact on the nozzle, tank wall and interference.

Of course, in addition to radar level sensors, ultrasonic level sensors are also a good choice for non-contact level measurement.

Frequently

Asked

Questions

Related Products

Related Blogs

Sino-Inst offers over 10 Radar Level Sensors for level measurement. At best price. About 50% of these are Radar level meters, 40% is the tank level sensor.

A wide variety of Radar Level Sensors options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Radar Level measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.