Radar water level sensor is the ideal solution for measuring the water level in dams, ponds, rivers, reservoirs, etc.

Radar water level sensor is Non-contact water level sensor, for long term surface water measurements. SIRD-908 Radar Water Level Sensor adopts a transmitting frequency up to 26GHZ. The antenna is made of corrosion-resistant materials such as stainless steel and PTFE. It is suitable for measuring the height of the liquid level of rivers, lakes, reservoirs, and groundwater media. The maximum distance can reach 30 meters. Output 4- 20mA or RS485 signal.

Sino-Inst offers a variety of Frequency modulated continuous wave radar for industrial level measurement. If you have any questions, please contact our sales engineers.

Features of SIRD-908 Radar Water Level Sensor

- All-weather work. 26GHz microwave reflection principle, strong anti-interference ability.

- The sensor has a reliable accuracy of 3 mm.

- No mechanical wear, non-contact measurement. Long life and easy maintenance

- The measurement has nothing to do with water quality. It is not affected by floating objects such as floating ice

- No need for wave wells. No effect on water flow

- Unattended continuous online collection

- Ultra-low power consumption. Support solar power supply

- It can be used for wireless network transmission. No need to excavate cable trench. It has no impact on the construction of channel lining and tree planting.

- Low cost. Simple installation and maintenance. Long life.

Specifications of SIRD-908 Radar Water Level Sensor

| Application: | Rivers, lakes, shallows |

| Measuring Range: | 30 meters |

| Process Connection: | Thread G1½ʺ A / bracket / flange |

| Process Temperature: | -40~100℃ |

| Process Pressure: | Atmospheric |

| Accuracy: | ±3mm |

| Protection Grade: | IP67 / IP65 |

| Frequency Range: | 26GHz |

| Supply: | DC (6-24V) / four wire DC 24V / two wire |

| Signal Output: | RS485/Modbus protocol 4~20mA/Hart two wires |

| Housing: | Aluminum single cavity / aluminum dual cavity / plastic / stainless steel single cavity |

| Explosion-proof Grade: | Optional |

Radar Water Level Sensor working principle

Measuring principle:

Micro-power microwave pulses are emitted from the radar antenna and travel through space at the speed of light. It is reflected by the object to be measured and received by the radar.

The time difference between the transmission and reception of the pulse signal is proportional to the distance from the radar antenna to the measured object. The propagation speed of electromagnetic signals in space is the speed of light. Usually when measuring the distance, the time difference between the transmitted pulse and the received pulse is very short and only on the order of nanoseconds.

Conventional technology is difficult to accurately measure this time.

SIRD-908 Radar Water Level Sensor uses an advanced equivalent sampling method to accurately measure the original nanosecond time interval. So as to realize the accurate measurement of distance.

Transmit-reflect-receive:

The extremely tiny 26GHz radar signal is emitted in the form of short pulses from the antenna end of the radar level gauge.

The radar pulse is reflected by the sensor environment and the surface of the object and received by the antenna as a radar echo.

The rotation period of the radar pulse from emission to reception is proportional to the distance, that is, the level.

◆ Input

The antenna receives the reflected microwave pulse and transmits it to the electronic circuit. The microprocessor processes this signal. Identify the echo generated by the microwave pulse on the surface of the material.

The correct echo signal identification is completed by intelligent software, and the accuracy can reach millimeter level. The distance D from the surface of the material is proportional to the time travel T of the pulse:

D=C×T/2

Where C is the distance of the empty tank at the speed of light E is known, then the distance of the level L is: L=E-D

◆ Output

It is set by entering the empty tank height E (=zero point), the full tank height F (=full scale) and some application parameters. Application parameters will automatically adapt the meter to the measurement environment. Corresponds to 4-20mA output.

Extended reading: Amazing Solutions for Continuous Liquid Level Measurement

Radar Water Level Sensor Applications

- River water level, automatic monitoring of open channel water level, water resource monitoring and water level measurement;

- In front of the reservoir dam, the tail water level monitoring and surge tower (well) water level monitoring below the dam;

- Automatic tide level monitoring system, urban water supply and sewage level monitoring system;

- Mountain flood warning system water level monitoring, water level monitoring of small and medium rivers.

Extended reading: Capacitive water level sensor

Extended Reading: 3 inch (3″) Water Flow Meter

More Water Level Sensors

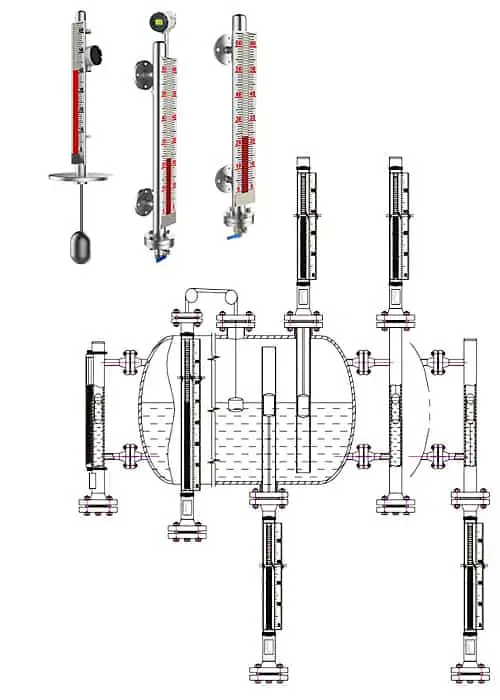

Sino-Inst offers a variety of water level sensors for a wide range of conditions. Our sensors are ideally suited for monitoring water levels in streams, dams and reservoirs. Our water level sensor products include:

- Submersible Pressure Transducers

- Radar Level Sensors

- Magnetostrictive Level Sensors

- Pressure Transducers

- Ultrasonic water level sensor

Frequently

Asked

Questions

Related Blogs

Sino-Inst offers over 10 Radar Water Level Sensors for level measurement. About 50% of these are Radar level meters, 40% is the tank level sensor.

A wide variety of Radar Water Level Sensor for level measurement options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Radar Water Level Sensor instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.