Absolute pressure transmitters measure the absolute pressure of the medium in the equipment. Its reference pressure is the absolute value 0 (vacuum), which has nothing to do with atmospheric pressure. Therefore, there is a vacuum sealed chamber on the low-pressure side of the pressure core.

When the fluctuation amplitude of the actual atmospheric pressure affects the process parameters beyond the allowable range, the use of absolute pressure transmitters is necessary. For example, in places where the local average atmospheric pressure deviates greatly from the standard atmospheric pressure.

Sino-Inst offers a variety of pressure senors for industrial pressure measurement. If you have any questions, please contact our sales engineers.

Absolute Pressure Transmitter Features

- Sensor Type : Industrial Pressure Transducers

- Full function buttons on site

- Pressure ranges: 0 … 1 mbar up to 0 … 600 bar

- Output/Span : 0 – 10 V, 0 – 5 V, 1 – 5 V, 10 mV/V, 4 – 20 mA, HART

- Pressure Port/Fitting : 1/2 MNPT, 1/4 FNPT, 1/4 MNPT, 1/8 MNPT

- Operating Temperature Range: -40 – 85 °C [ -40 – 185 °F ]

Extended reading: How to calibrate HART pressure transmitters

Specifications

| Application: | Liquid, gas or steam |

| Measurement range: | 0-41MPa |

| Output signal: | 4~20mAdc. output, superimposed HART protocol digital signal (two-wire system) |

| Power supply: | External power supply 24Vdc., power supply range 12V~45V |

| Hazardous location installation: | Explosion-proof type ExdIIBT5Gb; Intrinsically safe type ExialCT.4/T5/T6Ga; |

| Migration characteristics: | At the minimum range (range compression ratio is 40:1), the maximum positive migration zero point is 39/40 times the upper limit of the range. The maximum negative migration zero point can be the lower limit of the range. The absolute pressure transmitter has no negative migration. (No matter what the output form is, after the positive and negative migration, the upper and lower limits of the range shall not exceed the range limit) |

| Temperature range: | The electronic circuit board works at -40~85℃; the sensitive element works at -40~104℃; the storage temperature works at -40~85℃: with digital display works at -25~75℃ (operation); -40~85℃ (no damage) |

| Relative humidity: | 0~95% |

| Overpressure limit: | Range 3 to 8 withstand 0 (absolute pressure) ~13.78MPa, pressure transmitter without damage; range 9 pressure does not exceed 31.29MPa; range 0 pressure does not exceed 51.4MPa: normal working pressure is 3.43kPa (absolute pressure) to the upper limit of the range. |

| Volume change: | Less than 0.16cm3 |

| Damping: | The time constant is adjustable between 0.2~32.0s. |

| Accuracy: | ±0.1%, ±0.075% |

| Stability: | ±0.1% of the maximum range/12 months |

| Temperature effect: | The temperature error including zero point and range is ±0.2% of the maximum range/20℃ |

| Power supply effect: | Less than 0.005%/V of the output range. |

| Vibration effect: | In any axis, the frequency is 200Hz, and the error is ±0.05%/g of the maximum range. |

| Load effect: | As long as the voltage of the input transmitter is higher than 12V, there is no load influence in the load working area. |

| Installation position effect: | The maximum zero position error that can be generated is no more than 0.2kP, which can be eliminated by correction without affecting the range; the rotation of the measuring body relative to the flange has no effect. |

| Note: Under no migration, 316 stainless steel isolation diaphragm and other standard test conditions. | |

Order Guide

| Model | Transmitter type |

| GP | Pressure transmitter |

| AP | Absolute pressure transmitter |

| Code | Scale range |

| 2 | 0-0.10~3.5kPa(0-10~350mmH2O) |

| 3 | 0-0.8~8.0kPa(0-80~800mmH2O) |

| 4 | 0-4.0~40kPa(0-400~4000mmH2O) |

| 5 | 0-20~200kPa(0-2000~20000mmH2O) |

| 6 | 0-70~700kPa(0-0.7~7kgf/cm2) |

| 7 | 0-210~2100kPa(0-2.1~21kgf/cm2) |

| 8 | 0-700~7000kPa(0-7.0~70kgf/cm2) |

| 9 | 0-2.1~21MPa(0-21~210kgf/cm2) |

| 0 | 0-4.1~41MPa(0-41~4100kgf/cm2) |

| Code | Output form |

| E | Linear output 4-20mAdc |

| SF | Linear output 4-20mAdc+HART signal,Full function buttons on site |

| F | MODBUS-485 signal |

| Code | Pressure connection |

| L1 | 1/4NPT-18 Internal thread (excluding waist joint standard) |

| L2 | 1/2NPT-14 Internal thread |

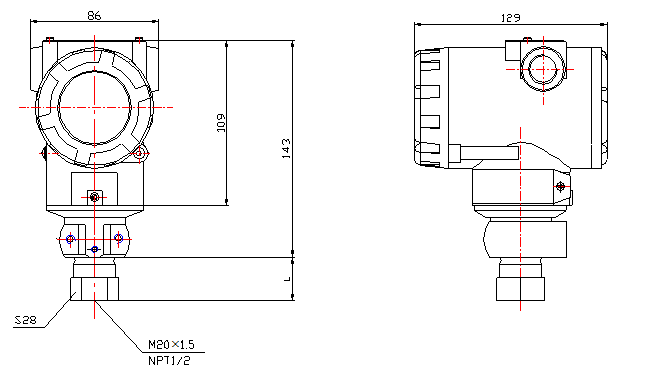

| L3 | M20×1.5 External thread |

| Code | Optional parts |

| M4 | LCD multi – power digital display head |

| B1 | Pipe bending bracket |

| B2 | Plate bending bracket |

| B3 | Pipe mounting bracket |

| D0 | The discharge valve is at the end |

| D1 | The side discharge valve is on the upper part |

| D2 | The side discharge valve is on the upper part |

| C02 | M20 x 1.5 nut and Φ 14 pressure short tube |

| C12 | 1/2NPT-14 external thread and Φ14 pressure short tube |

| C22 | 1/4NPT-18 external thread and Φ14 pressure short tube |

| C32 | 1/4NPT-18 to M20×1.5 external thread |

| C42 | 1/2NPT-14 to M20×1.5 external thread |

| C43 | 1/2NPT-14 to 1/4NPT-18 internal thread |

| C44 | 1/2NPT-14 to 1/2NPT-14 external thread |

| C45 | 1/2NPT-14 to G1/2 external thread |

| X1 | Oil ban |

| Gd | Measure the gold-plated membrane box |

| Da | Flameproof ExdIIBT5Gb;(explosion-proof certificate no. : CE16.1163) |

| Fa | Intrinsically safe ExiaIICT4 / T5 / T6Ga;(explosion-proof certificate no. : CE15.2354X) |

| Code | Flange connector | Exhaust/Drain valve | Isolation diaphragm | Filling liquid |

| 22 | 316 Stainless steel | 316 Stainless steel | 316 Stainless steel | Silicone oil |

| 23 | 316 Stainless steel | 316 Stainless steel | Hastelloy C | Silicone oil |

| 24 | 316 Stainless steel | 316 Stainless steel | Monel | Silicone oil |

| 25 | 316 Stainless steel | 316 Stainless steel | Tantalum | Silicone oil |

| 33 | Hastelloy C | Hastelloy C | Hastelloy C | Silicone oil |

| 35 | Hastelloy C | Hastelloy C | Tantalum | Silicone oil |

| 44 | Monel | Monel | Monel | Silicone oil |

| Code | Shell material | Conduit inlet dimensions | ||

| A | Low copper aluminum alloy polyurethane coating | M20×1.5 | ||

| B | Low copper aluminum alloy polyurethane coating | 1/2-14 NPT | ||

| C | Stainless steel | M20×1.5 | ||

| D | Stainless steel | 1/2-14 NPT |

Read more about: Common Units Of Pressure

What is the absolute pressure?

The pressure expressed with complete vacuum as the zero standard is called absolute pressure. Absolute pressure has only positive values.

What is absolute pressure transmitter?

Absolute pressure (AP) transmitter measure relative to perfect (full) vacuum pressure (absolute zero pressure).

Therefore, AP transmitters are not affected by fluctuations in the local atmosphere.

All absolute pressure measurements are positive. The letter ‘a’ or the abbreviation ‘abs’ in the unit of measure (i.e., inH₂O(abs) or psia) indicates an absolute pressure measurement.

Any critical storage and delivery (toxic gases) will change due to atmospheric conditions. So these systems must be accurate and use static references.

Absolute pressure transmitters are used in applications where the pressure of a gas or liquid is isolated from changes in atmosphere. For example, when testing a sealed pressure vessel for leaks for a long time.

How do absolute pressure sensors work?

The absolute pressure transmitter is mainly composed of two parts. One part is directly connected to the side to be measured. The other side is designed as an absolute vacuum reference chamber. This makes the two compartments form Absolute pressure. When the pressure on both sides is inconsistent, the difference signal will be transmitted through a special transmission line. The computer system in the background can calculate the difference. The pressure value on the measured side is directly displayed.

Applications for Absolute Pressure Sensors

- Absolute pressure sensors and absolute pressure gauges are often used for industrial high-performance vacuum pumps that need to be monitored.

- It is used to vacuum pack medical products in a clean environment. To ensure hygienic and sterile delivery to hospitals and doctors.

- In the food industry, vacuum packaging can be used when the highest possible vacuum is required to prevent oxygen from deteriorating perishable foods. This greatly extends the flavor and shelf life of the product.

- In meat packaging, a vacuum that meets the requirements must be generated. This can safely guarantee the longest shelf life.

- And pressure sensors affected by the atmosphere cannot monitor the high end of the vacuum.

- Applications that require true absolute pressure sensors and instruments can also be found in scientific laboratories, universities, military and aerospace industries.

Sino-Inst supplies Direct Mount Pressure / Absolute Pressure Transmitter.

Absolute pressure transmitter calibration

- First make a 4-20mA fine adjustment. It is used to calibrate the D / A converter inside the transmitter. Because it does not involve sensing components, no external pressure signal source is required.

- Do a full fine-tuning again. Make the 4-20mA, digital reading coincide with the actual applied pressure signal. Therefore, a pressure signal source is required.

- Finally, re-quantify the range. By adjusting the analog output 4-20mA and the external pressure signal source. Its function is exactly the same as the zero (Z) and range (R) switches on the transmitter shell.

Read more about: Absolute Pressure Vs Gauge Pressure Measuring Instruments

Absolute pressure transmitter VS Gauge pressure transmitter

Absolute pressure transmitter

Absolute pressure transmitter can realize absolute pressure measurement in equipment such as degassing system, distillation tower, evaporator and crystallizer, and allows pressure under 10Mpa. The δ chamber side of the absolute pressure transmitter receives the measured absolute pressure signal. The other side is sealed into a high vacuum reference chamber. Then convert it into 4 ~ 20mA DC signal output.

A gauge pressure transmitter in the general sense is mainly composed of a load cell sensor (also called a pressure sensor), a measurement circuit and a process connection. It can convert the physical pressure parameters such as gas and liquid felt by the load cell sensor into standard electrical signals (such as 4 ~ 20mADC, etc.), and provide secondary indicators such as alarm indicators, recorders, and regulators for measurement and indication. And process regulation.

More Featured Pressure Transmitters and Pressure Measurement Solutions

Sino-Inst is Chinese manufacturer of absolute pressure transmitters. SMT3151AP absolute pressure transmitters, are our main products, which are widely used in USA, South Africa, and other countries.

Contact us any time, if you need the quotation or technical support.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.