DP Level Transmitter uses pressure readings and the specific gravity of the medium to calculate the liquid level. Differential pressure level measurement is a common measurement technology. It can be used for closed-tank and open-tank level measurements.

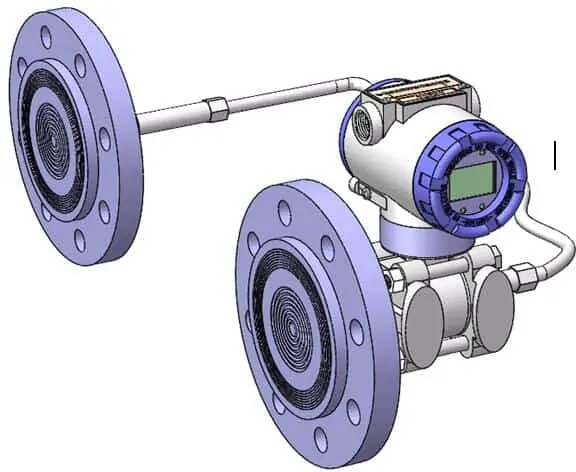

The DP Level Transmitter measurement system includes differential pressure transmitters, flanges, seal diaphragms, capillaries, wet legs/dry legs, and DP transmitters.

Sino-Inst offers a variety of DP Level Transmitters for industrial pressure measurement. Connection with diaphragm seals. If you have any questions, please contact our sales engineers.

Featured DP Level Transmitters

There are 5 types of remote transmission devices for remote differential pressure transmitters:

- Flat type

- Thread mounting type

- Flange mounting type

- Extended Diaphragm Seal

- Wet legs/Dry legs

Specifications of DP level transmitter

| Measuring medium | Liquids, gases, and steam | Pressure range | 0-0.1kpa-40mpa |

| Signal output | 4-20mA, superimposed Hart protocol, RS485 | Plywood material | All 316L stainless steel |

| Supply voltage | 12-30VDC | Precision | ± 0.2% FS, ± 0.1% FS, ± 0.075% FS (customizable) |

| Diaphragm material | 316L, customizable Ha C, tantalum, Monel alloy | Temperature compensation | -10 ~ + 70 ℃ |

| Long-term stability (1 year) | ≤ ± 0.25% FS | Operating temperature | -20 ~ + 100 ℃ |

| Overload pressure | 200% FS | Zero range | External continuously adjustable |

| Destruction pressure | 300% FS | Power effect | Less than 0.005% / V of the output range |

| Weight | 3.9KG (standard type) | Protection level | IP65 |

| Volume uptake | Less than 0.16cm3 | Load impact | If the power supply is stable, the load has no effect |

Applications of DP level transmitters

The differential pressure liquid level transmitter can prevent the measured medium from directly contacting the sensor diaphragm of the transmitter. It is suitable for the following situations:

- When the measured medium has a corrosive effect on the transmitter connector and sensitive components;

- When the high temperature measured medium needs to be isolated from the transmitter;

- When there are solid suspended solids or high viscosity in the measured medium, it is easy to block the transmitter connector and the pressure chamber;

- When the measured medium is easily cured or crystallized by the pressure tube;

- When changing the measured medium needs to be rinsed and not to be mixed;

- Hygienic conditions must be maintained to prevent pollution. .

- Changing the measured medium requires strict purification of the measuring head

- Suspended liquid or high viscosity medium

- Measurement of sealed pressure vessel.

Read more What is a diaphragm seal?

Differential pressure type level transmitter working principle

The differential pressure level transmitter is an instrument that uses the pressure generated by the liquid column to measure the height of the liquid level. When the liquid level changes, the pressure received by the diaphragm at the high-pressure side flange will change accordingly. The differential pressure value calculated by the transmitter will also change accordingly. There is a linear relationship between them.

Normally, the high-pressure side (H side) and the low-pressure side (L side) cannot be installed reversely. Generally, the H side is installed at the lower part of the equipment, and the L side is installed at the higher part of the equipment. Before installation, the flange surface of the equipment should be cleaned and the gasket should not be placed off-center to prevent the diaphragm from being punctured or deformed, causing distortion of the transmitter.

Differential pressure transmitter level measurement calculation

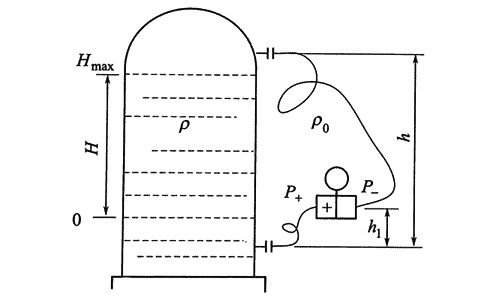

When using a Differential pressure (DP) level transmitter to measure the liquid level as shown in the figure below.

The measured liquid density in the figure is ρ.

The working medium density in the capillary of the double flange differential pressure transmitter is ρ0.

The measuring range of the measured liquid level is H.

The center distance of the sampling tube of the measured liquid level is h.

It can be seen from the figure that the maximum measurement range of the liquid level △ P = P + — P- = H × ρ × g – h × ρ0 × g.

It can be seen from the formula that the dual-flange differential pressure transmitter should perform negative migration. The migration amount S is h × ρ0 × g. And the installation position of the double flange differential pressure transmitter has no effect on the migration amount and the measurement result.

The dual-flange differential pressure transmitter requires negative migration.

When the measured liquid level is 0, the pressure difference between the positive and negative measurement chambers of the remote differential pressure transmitter is the largest. The output current of the double flange differential pressure transmitter is 4mA.

As the measured liquid level rises, the pressure difference between the positive and negative measurement chambers of the transmitter gradually decreases.

When the measured liquid level rises to the highest Hmax. The pressure difference between the positive and negative measurement chambers of the transmitter is the smallest. The output current of the double flange differential pressure transmitter is 20mA.

Read more about: Differential Pressure Transmitter Installation Guide

DP level transmitter calibration

The differential pressure liquid level transmitter has been calibrated in the range, accuracy, linearity and other parameters according to customer requirements at the factory. And mark the range, accuracy, etc. on the nameplate of the differential pressure liquid level transmitter. As long as the density and other parameters of the measured medium meet the requirements of the nameplate, generally no adjustment is required.

If the customer needs to adjust the range or zero position, please adjust according to the following methods. Assuming that the range of the differential pressure liquid level transmitter is 0 ~ 10 meters:

- Unscrew the protective cover of the differential pressure liquid level transmitter. It can be adjusted by connecting an external standard 24VDC power supply and ammeter (requires accuracy of 0.2% or above).

- When there is no liquid in the differential pressure liquid level transmitter. Adjust the zero potentiometers. Make it output a current of 4mA.

- Pressurize the differential pressure liquid level transmitter to full scale (10 meters). Adjust the full-scale resistor. Make it output a current of 20mA.

- Repeat the above steps two or three times until the signal is normal.

- Please input 25%, 50%, and 75% signals to check the error of the differential pressure liquid level transmitter.

- For non-aqueous media. Differential pressure level transmitters are calibrated with water. It should be converted according to the pressure generated by the actual density of the medium. For example, when the medium density is 1.3, the 1.3m water level should be used to calibrate the 1m range.

- After adjustment, tighten the protective cover.

- The verification cycle of the differential pressure liquid level transmitter is once a year.

- HART intelligent differential pressure liquid level transmitter of Sino-Inst instrument can be selected. It is convenient to adjust the range of the differential pressure liquid level transmitter.

Extended reading: How to calibrate HART pressure transmitters

You may like: pressure level transmitter

More Pressure and Level Measurement Solutions

- Differential Pressure Transmitter Installation Guide

- MEMS Pressure Sensors

- Application Analysis of Intelligent Pressure Transmitter

- Differential Pressure Flow Meters

- Water Pressure Sensors for Measurement of Water Pressure

- Pressure Sensor Applications-Featured Industry Applications

- Flow Pressure Transducers for Fluid Pipelines

- Pressure Transducer Wiring Diagram Guide: 2 Wire-3 Wire-4 Wire

- Amazing Solutions for Continuous Liquid Level Measurement

- The Secret of Ultrasonic Level Measurement

- 7 Type Tank Level Senors For Liquid and Solid

- Guide to Ultrasonic Level Transmitters-for Continuous Non Contact Level Measurement of Liquid & Solids.

Sino-Inst (drurylandetheatre.com) offers over 20 DP transmitters for liquid level, pressure, flow, and density measurement. Differential pressure (DP) level transmitters are suitable for measuring water and other liquid level.

We are a differential pressure level transmitter supplier, located in China. Our products are widely exported to the United States, Australia, Singapore, Indonesia, etc. You can ensure product safety by selecting from our products, including IOS9000, and… certification.

If you need to purchase DP Level Transmitters or have related technical questions, please feel free to contact our sales engineers!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.