Steam pressure transmitters are widely used in the measurement and control of various high-temperature steam piping systems. The monitoring of steam pipes is very important. To measure the pressure of steam pipes, have you encountered the following problems:

- Don’t know which pressure transmitter to choose?

- Is it good to use a high-temperature pressure transmitter to measure the pressure of the steam pipe?

- The core of the pressure transmitter removed at the steam site. The diaphragm has been dented by the impact. Is it scrapped directly?

- How to choose the type and what should be paid attention to when measuring the steam pipeline?

Steam pressure transmitter performance

Extended Reading: Smart pressure transmitter

Related Products:

High pressure sensor is pressure transmitter designed for high pressure measure&control. 0 ~ 40MPa… 600MPa. M20 × 1.5, G1 / 2 (others are customized according to requirements)

Pressure sensor for Ultra high pressure applications. Ultra high pressures up to 15,00MPa. 0-2000MPa to 0-7000MPa (customized).Ball head M20 × 1.5, cone head M20 × 1.5.

High Temperature Pressure Sensor for pressure measurement of high temperature gas or liquid. Such as steam pressure. High temperature up to 800 ℃.

Silicon pressure sensor, also known as Diffused silicon pressure sensor. Silicon pressure sensors are low cost.

Combined pressure and temperature sensor for Simultaneous measurement of pressure and temperature.

Thermocouple types: J, K, E type or PT100 platinum resistance. Two outputs do not affect each other.

Extended reading: Featured Diaphragm Seal Pressure Transmitters

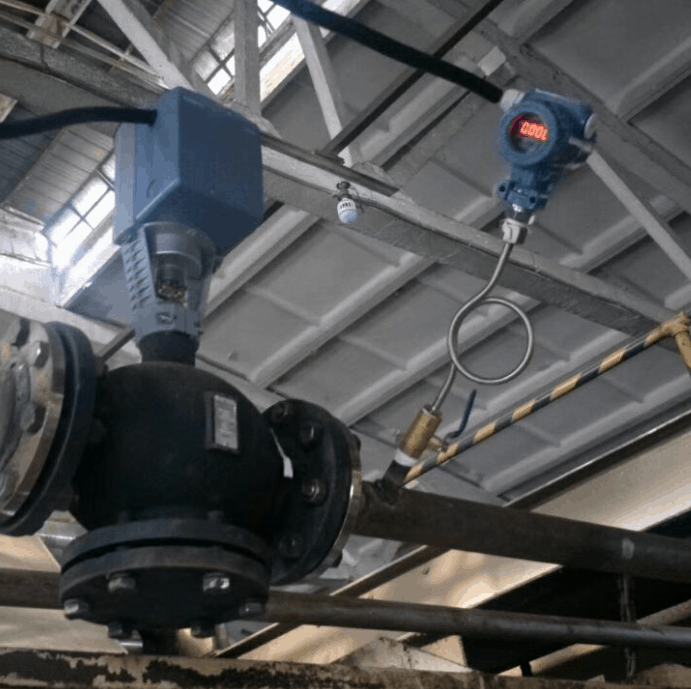

Steam pressure transmitter installation

- When wiring, pass the cable through the waterproof connector (accessory) or flexible tube and tighten the sealing nut to prevent rainwater from leaking into the transmitter housing through the cable.

- Prevent the pressure transmitter from contacting corrosive or overheated media;

- When measuring the liquid pressure, the installation position of the transmitter should avoid the impact of the liquid (water hammer phenomenon) to avoid damage to the sensor overpressure;

- When measuring the liquid pressure, the pressure port should be opened on the side of the processing pipeline to avoid precipitation and slag;

- When measuring gas pressure, the pressure tap should be opened at the top of the process pipeline. The transmitter should also be installed on the upper part of the processing pipeline. So that the accumulated liquid can be easily injected into the processing pipeline;

- Prevent dross from depositing in the duct;

- When measuring steam or other high-temperature media, a buffer tube (coil) and other condensers should be connected. The working temperature of the pressure transmitter should not exceed the limit;

- When freezing occurs in winter, the transmitter installed outdoors must take anti-freezing measures. Avoid volume expansion of the liquid in the pressure inlet due to icing, leading to damage to the sensor;

- The pressure guiding tube should be installed in a place with small temperature fluctuations;

Read more about: What is a pressure sensor and how it works?

What should be paid attention to when measuring the pressure on the steam pipeline?

Pressure transmitters are used for steam metering and pipeline monitoring.

The temperature in the steam pipeline is generally relatively high. The low is more than one hundred degrees Celsius, and the high is two to three hundred degrees Celsius.

The start and stop of the valve will also cause the pressure in the pipeline to fluctuate.

Today we are going to talk to you about what to pay attention to when measuring the pressure of steam pipes?

Extended Reading: Up to 800°C High Temperature Pressure Sensor

You may like:

Extended Reading: Digital Pressure Sensor-RS485

Sino-Inst offers over 10 Steam Pressure Transmitters. A wide variety of Steam Pressure Transmitter options are available to you. Such as free samples, paid samples.

Sino-Inst is a globally recognized manufacturer of Steam Pressure Transmitters, located in China. Sino-Inst sells through a mature distribution network that reaches all 30 countries worldwide. Steam Pressure Transmitter products are most popular in Europe, Southeast Asia, and Mid East. You can ensure product safety by selecting certified suppliers. With ISO9001, ISO14001 certification.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.