Coriolis Mass Flowmeter is suitable for measuring various non-Newtonian fluids, slurries, suspensions, high viscosity fluids and other media.

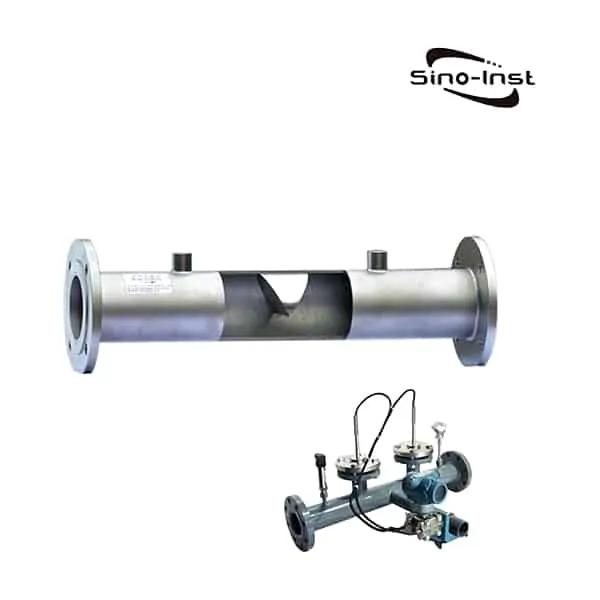

The T-series Triangle Coriolis Mass Flowmeter can directly measure the mass flow rate of the fluid in the closed pipe and the density of the medium. The T series Coriolis mass flowmeter has a triangular sensor structure. The smallest diameter can be DN3. This structure flowmeter is easy to measure when the instantaneous flow is small. The compact triangular shell structure saves installation space. The installation is simple and superior Downstream straight pipe requirements

Sino-Inst offers a variety of Mass flow meters for High Viscosity Liquids flow measurement. If you have any questions, please contact our sales engineers.

Features of T-series Triangle Coriolis Mass Flowmeter

- Triangular internal measuring tube design.

- It can directly measure the mass flow of fluids. This is of great significance for the measurement and control of production processes such as energy metering and chemical reactions.

- High measurement accuracy. The measurement accuracy can be guaranteed between 0.1% and 0.5%.

- The measurable ratio is relatively large. Generally, the measurable ratio to ensure the basic accuracy is 10:1 or 20:1.

- Wide application range. In addition to normal fluid measurement, it can also measure industrial media that are difficult to measure with general fluid measuring instruments, such as high-viscosity fluids, various slurries, suspensions, etc.

- .Completely provide mass flow, volume flow, density, temperature measurement and calculation parameters. Reliable results can be obtained without tedious conversion, and volume tables can be directly replaced.

- Compact triangular shell structure. Save installation space and simple installation. No upstream and downstream straight pipe section requirements

- Simultaneously measure the instantaneous flow rate, cumulative flow rate, temperature, density

- Direct measurement of fluid quality. The measurement accuracy is not affected by temperature, pressure, density, viscosity, without any compensation conversion

- No need to re-calibrate when measuring fluid changes

Extended reading: Liquid mass flow controller for process liquid -Sino-Inst

Specifications of T-series Coriolis Mass Flowmeter

Sensor technical parameters:

(1) Sensor specification, range, zero stability:

| Diameter (DN) | Flow Range | Zero stability |

| mm | kg/h | kg/h |

| 3 | 0~96~144 | 0.0144 |

| 6 | 0~540~810 | 0.081 |

| 8 | 0~960~1440 | 0.144 |

| 10 | 0~1500~2250 | 0.225 |

| 15 | 0~3000~4500 | 0.45 |

| 20 | 0~6000~9000 | 0.9 |

| 25 | 0~9600~14400 | 1.44 |

| 32 | 0~18000~27000 | 2.7 |

| 40 | 0~30000~45000 | 4.5 |

| 50 | 0~48000~72000 | 7.2 |

| 80 | 0~120000~180000 | 18 |

| 100 | 0~192000~300000 | 30 |

| 150 | 0~36000 | 60 |

Note: The flow range gives two parameters, the middle parameter is the standard flow range, and the general factory inspection is carried out according to this range. At the same time, it is also recommended that the user choose the instrument within this range. The latter parameter is the upper limit flow to ensure the stable operation of the sensor scope.

(2) Flow (liquid) measurement accuracy

| Flowmeter Accuracy | Measurement error | repeatability |

| 0.10% | ±0.1% ±(zero point stability/measured value)% | 1/2 measurement error% |

| 0.15% | ±0.15% ±(zero point stability/measured value)% | 1/2 measurement error% |

| 0.20% | ±0.2% ±(zero point stability/measurement value)% | 1/2 measurement error% |

Read more about: The Pros and Cons of Micro Motion Flow Transmitters

(3) Density (liquid) measurement range and accuracy

Measuring range: 0.3~3.000g/cm3 Measuring accuracy: ±0.002g/cm3

(4) Temperature measurement range and accuracy

Measuring range: -200~350°C Measuring accuracy: ±1°C

(5) Working temperature of the measured medium: -200℃~350℃

Standard type: -50~200℃

Low temperature type: -200~200℃

(6) Applicable ambient temperature: -40℃~60℃

(7) Material: measuring tube 316L shell 304

(8) Working pressure: 0~4.0MPa

Note: The actual withstand voltage of the sensor varies from specification to specification, here is only the standard withstand voltage.

(9) Explosion-proof mark: Exd[ia]ⅡCT6Gb

Extended reading: What Is Difference Between Rotameter And Flow Meter?

Converter parameters

(1) Measurement parameters: mass flow, volume flow, medium working density, medium working temperature

Display: double-row LED display, three-row LCD display

Window size: 62×32mm (W×H) (Φ80mm)

Measurement display accuracy: 0.05%

Measurement display unit: mass flow g/h, kg/h, t/h, g/m, kg/m, t/m

Volume flow cm3/h, dm3/h, m3/h, cm3/m, dm3/m, m3/m

Density kg/m3 or g/cm3

Temperature °C, K, °F

(2) Converter output signal

Converter output signal: 0~10000Hz pulse signal

Flow signal Collector open circuit signal 4~20mADC current signal

Flow, density output signal choose one of the current output load capacity: not less than 750 ohms (24VDC power supply)

Note: Two current signals can be provided as required

Output signal accuracy: pulse signal 0.05%

Current signal 0.2%

Communication signal: RS485 MODBUS protocol

(3) Operating ambient temperature -40~60℃

Power supply 18~36VDC Power supply: 7W (basic power supply)

85~265VAC power supply: 10W (additional power supply)

(5) Instrument protection and explosion-proof protection level: IP67

Explosion-proof grade: Exd[ia]ⅡCT6Gb\Exd [ib]ⅡCT6Gb

(6) Structural size and weight Φ125×180mm, 2.7kg

Coriolis Mass Flowmeter Working Principle

The principle of Coriolis mass flowmeter mass measurement is Newton’s second law F=Ma. When the fluid flows in the vibrating tube, it will produce Coriolis force proportional to the mass flow.

When there is no fluid flowing, the vibrating tube will not be twisted, and the signals detected by the electromagnetic signal detectors on both sides of the vibrating tube are in phase.

When fluid passes by, the vibrating tube will be twisted under the action of torque, and there will be a phase difference between the two detectors.

The transmitter measures the lag time between the left and right detection signals. This time difference is multiplied by the flow calibration coefficient to determine the mass flow.

The density measurement principle of Coriolis mass flowmeter is that the vibration frequency is inversely proportional to the square root of the fluid density. The fluid density is determined by measuring the vibration frequency.

Therefore, the mass flow meter can realize the measurement of fluid mass flow and the measurement of fluid density.

How does a T-series Triangle Coriolis Mass Flowmeter measure mass flow and density?

Coriolis mass flow measurement is the MOST ACCURATE FORM for a flow measurement for a wide range of industrial processes. Each Coriolis flowmeter has one or more measuring tubes.

As soon as the fluid starts to flow in the measuring tube, additional twisting is imposed on this oscillation due to the fluid’s inertia. Two sensors detect this change of the tube oscillation in time and space as the “phase difference.”

Phase difference= mass flow

Oscillation frequency= density

More Featured Flow Meters

More Feature Flow Measurement Solutions

Sino-Inst, Manufacuturer for Coriolis Mass Flowmeters.

T-series Triangle Coriolis Mass Flowmeter simultaneously measures mass flow, density, temperature and viscosity.

Sino-Inst’s T-series Triangle Coriolis Mass Flowmeters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.