Tuning fork density meter is also called density analyzer , fork densitometer or density sensor. Tuning fork density meter is a process control instrument for density as the primary control parameter, or an online analysis instrument for other quality control parameters such as solid percentage. Continuous and real-time online measurement of fluid density. The Tuning fork density meter is installed on the pipeline, in an open or closed storage tank, and the density of the detected fluid depends directly on the vibration frequency received by the tuning fork in the medium where the sensor is inserted.

Features of Tuning Fork Density Meter

Technical Parameters

| Measuring range | 0 – 2.5 g /cc (0 – 2500 kg/m3),0~100.0% |

| Calibration range | 0 – 2.5 g /cc (0 – 2500 kg/m3),0~100.0% |

| measurement accuracy | ± 0.001 g /cc (± 1 kg/m3) ,±0.5% |

| repeatability | ± 0.001 g /cc (± 0.1 kg/m3) ±0.1% |

| Operating temperature range | -50℃ ~ +150℃ |

| working pressure | 4mpa |

| Fluid Viscosity Range | 0 – 2000 cP |

| Temperature Coefficient | Less than 0.1 kg/m3 /°C (±0.5%) after correction |

| pressure effect | negligible |

| Built-in temperature sensor | Digital sensor, temperature compensation |

| Wetted material | 316L, 2205, 2507 Stainless Steel, Ha C, Titanium, PTFE/PFA |

| Fork Coating | Standard PTFE or PFA |

| Power supply | 24VDC, ≥50mA |

| Analog signal output | 4-20mA, 0-1000Hz, RS485 Modbus RTU HART |

| Output accuracy (20℃) | ± 0.1% of reading or ± 0.05% FS |

| Output repeatability (-40 ~ +85°C) | ± 0.05% FS |

| process connection | DIN 50 PN16 G1.5″ Thread, 3″ Chuck, IDF and RJT Sanitary |

| degree of protection | IP65 |

| shell | aluminum alloy |

- Model: Alcohol Concentration Meter

- Length: 150mm

- Measuring range: 0-2.5g/cc(0-100%)

- Measurement accuracy: 0.002g/cm3 (0.5%)

- Voltage: DC24V

- Explosion-proof: Exd IICT6 Gb

- Electrical interface: M20*1.5

- Wetted material: 316L, built-in temperature sensor

- Liquid crystal display: density, concentration, specific gravity, temperature

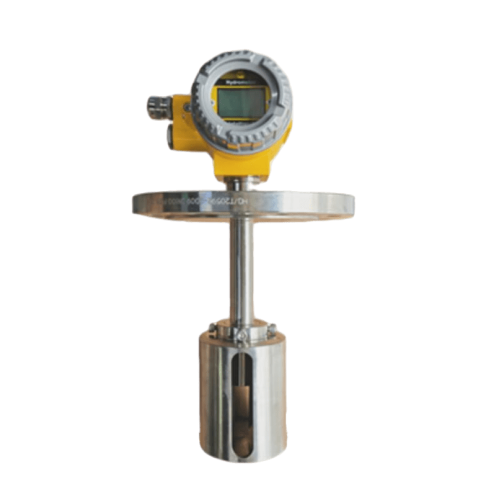

- Model: Submersible tuning fork density meter

- Four-wire system/two-wire system

- Power supply: DC24V

- Connection method: DN50PN16

- Insertion length: 10m

- Wetted material: 316L stainless steel

- Output: 2-way 4-20Ma+RS485/MODBUS

- Electrical interface: M20*1.5

- Display: Four digits after the decimal point, LCD, remote PLC/DCS

- Junction box: aluminum alloy

- Model: Anti-corrosion tuning fork density meter

- Four-wire system

- Power supply: DC24V

- Connection method: DN50PN16

- Insertion length: 150mm

- Wetted material: 316L stainless steel lined with PTFE

- Output: 2 channels 4-20Ma+RS485/MODBUS/HART

- Electrical interface: M20*1.5

- Display: four digits after the decimal point, LCD, remote PLC/DCS

- Junction box: aluminum alloy

- Model: Threaded tuning fork density meter

- Four-wire system

- Power supply: DC24V

- Connection method: G1-1/2 thread

- Insertion length: 150mm

- Wetted material: 316L stainless steel

- Can be customized (ha C, titanium, 2205, 2507

- Duplex stainless steel, load)

- Output: 2 channels 4-20Ma+RS485/MODBUS/HART

- Electrical interface: M20*1.5

- Display: Four digits after the decimal point, LCD, remote PLC/DCS

- Junction box: aluminum alloy

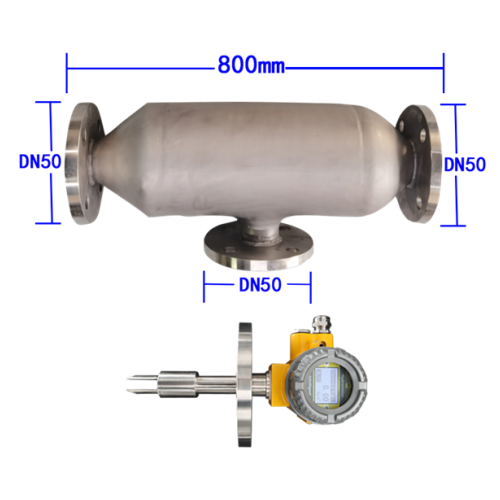

- Model: Flange standard tuning fork density meter

- Four-wire system (for measuring lime slurries, mud, etc.)

- Power supply: DC24V

- Connection method: DN50PN16-20592

- Insertion length: 150mm

- Wetted material: 316L stainless steel

- Can be customized (ha C, titanium, 2205, 2507

- duplex stainless steel, aluminum, PTFE/PFA)

- Output: 2 channels 4-20Ma+RS485/MODBUS/HART

- Electrical interface: M20*1.5

- Display: Four digits after the decimal point, LCD, remote PLC/DCS

- Junction box: aluminum alloy

- Built-in temperature sensor, automatic compensation

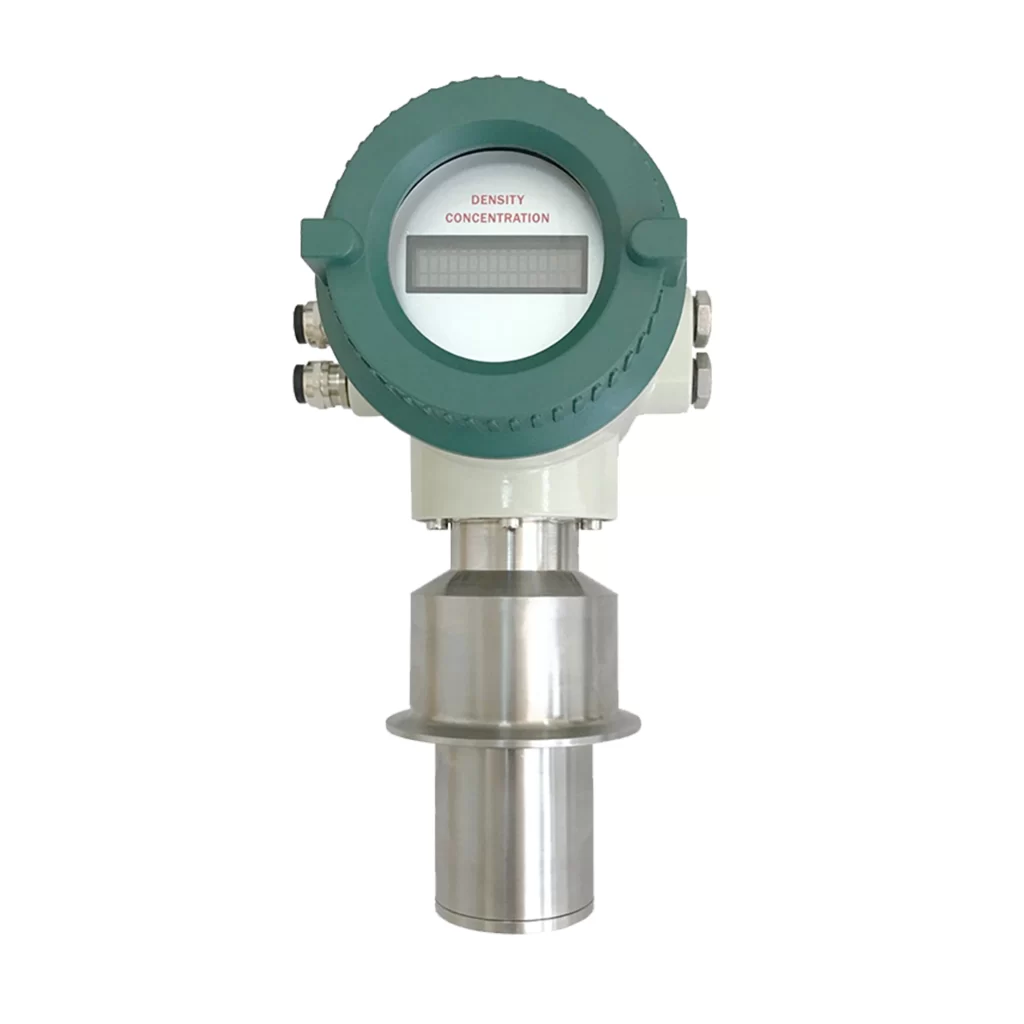

- Model: Sanitary Chuck type tuning fork density meter

- Four-wire system

- Power supply: DC24V

- Connection method: 3 inch chuck

- Insertion length: 150mm

- Wetted material: 316L stainless steel

- Can be customized (ha C, titanium, 2205, 2507

- duplex stainless steel, tan, PTFE/PFA)

- Output: 2 channels 4-20Ma+RS485/MODBUS/HART

- Electrical interface: M20*1.5

- Display: Four digits after the decimal point, LCD, remote PLC/DCS

- Junction box: aluminum alloy

- Built-in temperature sensor, automatic compensation

- Model: Top Mounted Rod Tuning Fork Density Meter

- Four-wire system/two-wire system

- Power supply: DC24V

- Connection method: DN50PN16

- Insertion length: 3m (shield type)

- Wetted material: 316L stainless steel

- Output: 2 channels 4-20Ma+RS485/MODBUS/HART

- Electrical interface: M20*1.5

- Display: density, concentration, temperature, remote PLC/DCS

- Junction box: aluminum alloy

- Built-in temperature sensor, automatic compensation

- Model: Pool tank or special type with stirring tank

- Four-wire system

- Power supply: DC24V

- Connection method: DN50PN16

- Insertion length: 150mm

- Wetted material: 316L stainless steel

- Can be customized (ha C, titanium, 2205, 2507

- duplex stainless steel, tan, PTFE/PFA)

- Output: 2 channels 4-20Ma+RS485/MODBUS/HART

- Electrical interface: M20*1.5

- Display: four digits after the decimal point, LCD

- Junction box: aluminum alloy

- Built-in temperature sensor, automatic compensation

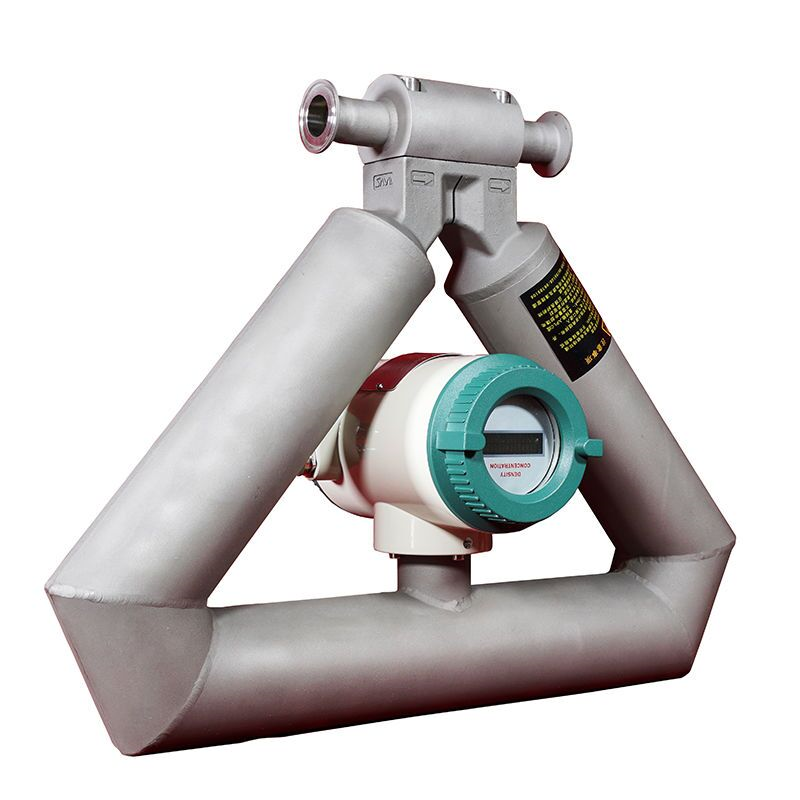

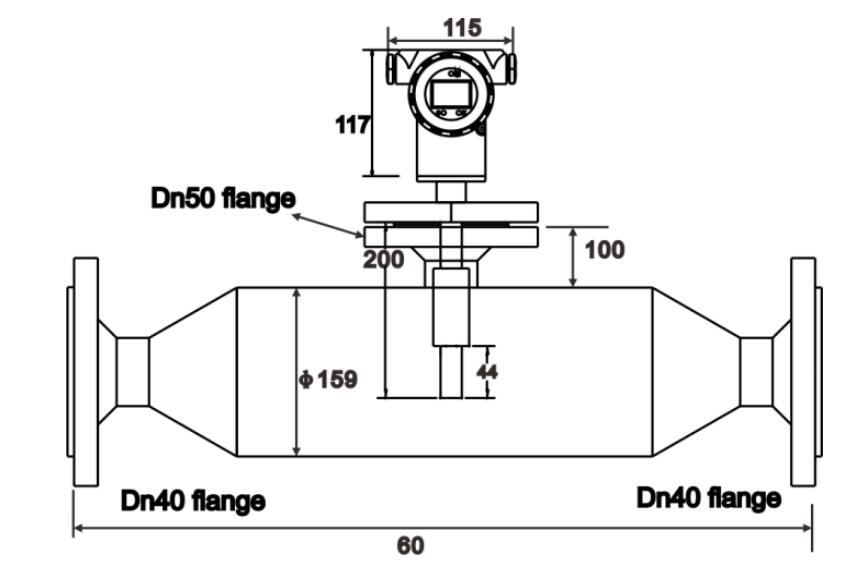

Measuring Barrel

fork density meter principle

Tuning fork density meter (concentration meter) can perform density detection online in real time. It can be applied to the process control of products with density as the basic parameter or the quality control with solid percentage or concentration percentage as reference.

Typical industries include petrochemical industry, brewing industry, food industry, pharmaceutical industry and mineral processing (such as clay, carbonate, silicate, etc.). Specifically used in the interface detection in multi-product pipelines in the above industries, the density detection of stirred mixtures, the end point monitoring of reactors, and the interface detection of separators.

Tuning fork density sensors work on the principle of vibration of components, which are part of the tuning fork immersed in the liquid to be measured. The tuning fork part is vibrated by an internal piezoelectric device fixed at the bottom end of the fork body. The oscillation frequency is detected by a secondary piezoelectric device fixed at the other end of the fork. The signal is then amplified by the circuit on top. The density of the liquid is closely related to the vibration frequency when the measured liquid flows. When the density of the measured liquid changes, the vibration frequency of the liquid changes accordingly.

Through the following equation, the density of the measured liquid can be accurately calculated.

D= K0+K1T+K2T2

D = uncalibrated density of the measured medium (kg/m3)

T=vibration frequency (μs).

K0, K1, K2 = constant

During the density detection process, the Tuning fork density meter (concentration meter) can automatically compensate the influence of temperature on the density (D) of the measured medium. Pressure has no significant effect on density.

Read More About: What Is Density Meter? and Types

Tuning Fork Density Meter Application

Tuning fork density meters are suitable for measuring the density of various types of liquids and solid substances.

Its application range is quite wide, including but not limited to the following types of substances:

- Liquids: water, solutions, alcohols, petroleum, chemicals, liquid metals, etc.

- Solution: solid or gas dissolved in a solvent, such as salt water, acid-base solution, dissolved matter in an organic solvent, etc.

- Oil: various types of lubricating oil, mechanical oil, edible oil, etc.

- Chemicals: various chemicals, solvents, acids and bases, etc. nitric acid, phosphoric acid, acetic acid, chloroacetic acid, potassium hydroxide, sodium chloride, sodium sulfate, ammonium sulfate, ammonium bisulfate, ammonium chloride, carbamide, ferric chloride, ammonia, hydrogen peroxide

- Fuel: gasoline, diesel, liquefied petroleum gas (LPG), aviation fuel, crude oil, kerosene, silicone oil, etc.

- Plastics: Different kinds of plastic materials, resins, etc.

- Metal: liquid metal, alloy, etc.

- Food and beverages: milk, juice, beer, wine, etc.

- Organic chemical industry: ethanol, methanol, ethylene, toluene, ethyl acetate, ethylene glycol, thinner water

- Medicine: pharmaceutical intermediates, solvents, polyvinyl alcohol (PVA), citric acid, lactic acid

- Semiconductors: high-purity solvents, detergents, isopropanol, butyl acetate

- Printing and dyeing: sodium hydroxide, sodium carbonate, sodium bicarbonate

- Equipment: cutting fluid, emulsified oil, cutting oil, lubricating oil, antifreeze

- Batteries: hydrochloric acid, sulfuric acid

Typical application industries:

- Chemical measurement;

- reservoir measurement;

- Slurry measurement;

- Medicine tank measurement;

- Cement measurement;

- printing and dyeing measurement;

- Waste acid tower measurement;

- power plant measurement;

Please note that different models of tuning fork densitometers may have limited range of application. Specific measurement ranges and accuracies may depend on equipment specifications and manufacturer’s instructions. Therefore, before choosing a tuning fork density meter for specific material density measurements. It is best to refer to the technical specifications and instructions for use of the equipment to ensure that it is suitable for the substance of interest.

case study

A customer consulted us and needed to measure the density in the sediment pipe dug out by the dredger.

For dredger applications:

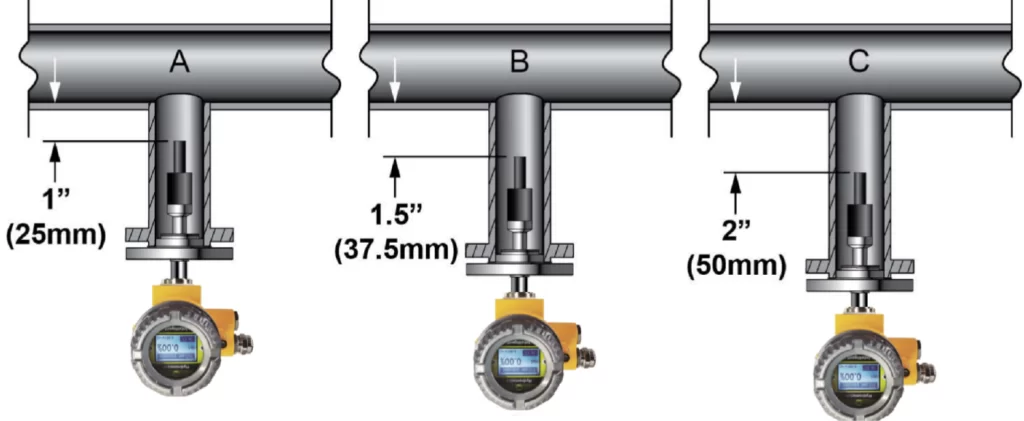

- Installation size: pipe with a diameter of 30cm

- Insertion Depth Length: 2”

- Wetted material: mud sand

- Need signal output: 4-20ma

- Pressure: 0-10bar

- Density (or concentration) range: 0-2000kg/m3

Combined with the user’s measurement parameters, we have configured a density meter for the user:

Tuning Fork Density Meter:

- A layer of wear-resistant material is added to the 316 sensor

- Power supply DC24V,

- Medium: Mud,

- Pressure: 0-10bar,

- DN50 flange connection,

- Insertion depth: 180mm,

- Material: 316+ wear-resistant coating,

- Output 4-20mA four-wire system + RS485,

- Density (or concentration) range: 0-2000kg/m3,

- Installation size: pipe with a diameter of 30cm,

- English interface

FAQ

More Measurement Solutions

Liquid Level Sensor Probes Types and How to Select

What Is the Ultrasonic CO2 Level Indicator? CO2 Bottle Level Measuring Device

Dew Point Monitor for the Fruit and Vegetable Industry

Radar Level Gauge – Everything You Should Know and Selection List

What Is a Dew Point Monitor and How to Choose One?

What Are Flow elements? Guide for Different Types of Flow Elements

Density is an important parameter in the industrial production process. Density measurement is a very professional field. Different media have different physical properties. Only by selecting suitable instruments according to different media properties can accurate and reliable measurements be made. Unique performance is brought into play.

Sino-Inst is a manufacturer of tuning fork density meters. Our tuning fork density meters are used in a wide variety of industries. Including, petrochemical industry, brewing industry, food industry, pharmaceutical industry and mineral processing (such as clay, carbonate, silicate, etc.). Different media require different densitometers. You can contact our sales engineers for technical support and quotation for tuning fork density meters.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

Tuning Fork Density Meter | Sino-Inst

Tuning fork density meter is also called density analyzer , fork densitometer or density sensor. Tuning fork density meter is a process control instrument for density as the primary control parameter, or an online analysis instrument for other quality control parameters such as solid percentage. Continuous and real-time online measurement of fluid density. The Tuning fork density meter is installed on the pipeline, in an open or closed storage tank, and the density of the detected fluid depends directly on the vibration frequency received by the tuning fork in the medium where the sensor is inserted.

Product SKU: Tuning Fork Density Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 1850

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5