Turbine flow meters are velocity flow meters, also called impeller flow meters. Can be used to measure the instantaneous flow and cumulative flow of liquids and gases.

Turbine flowmeters are widely used in flow measurement: petroleum, organic liquids, inorganic liquids, liquefied gas, natural gas, coal gas and cryogenic fluids. Turbine flowmeter signals can be divided into pulse signals or current signals (4-20mA). It is suitable for use with secondary display, PLC, DCS and other computer control systems.

Turbine Flow Meter reference price: USD 200-1700/pc.

Sino-Inst offers a variety of Turbine flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Featured Turbine Flow Meters

Features of Turbine Flow Meters

- High accuracy, good repeatability, low pressure loss, good vibration resistance;

- Adopt high-quality bearings with low friction resistance. Good sealing and long life;

- It integrates microprocessor, flow sensor, high-precision temperature and pressure sensor. Directly measure the flow, temperature and pressure of the gas/liquid being measured. And automatically perform flow tracking compensation and compression factor correction operations;

- The meter has pulse signal and analog signal output. It can directly realize the centralized collection and real-time management of computer data through the RS485 communication interface or the GPRS system;

- Low power consumption. It can be powered by internal battery or external power supply;

- With real-time data storage function. It can prevent data loss when the battery is replaced or the power is suddenly lost. In the case of power failure, internal data can be stored permanently;

- It can be used in conjunction with IC card prepayment system to facilitate trade settlement;

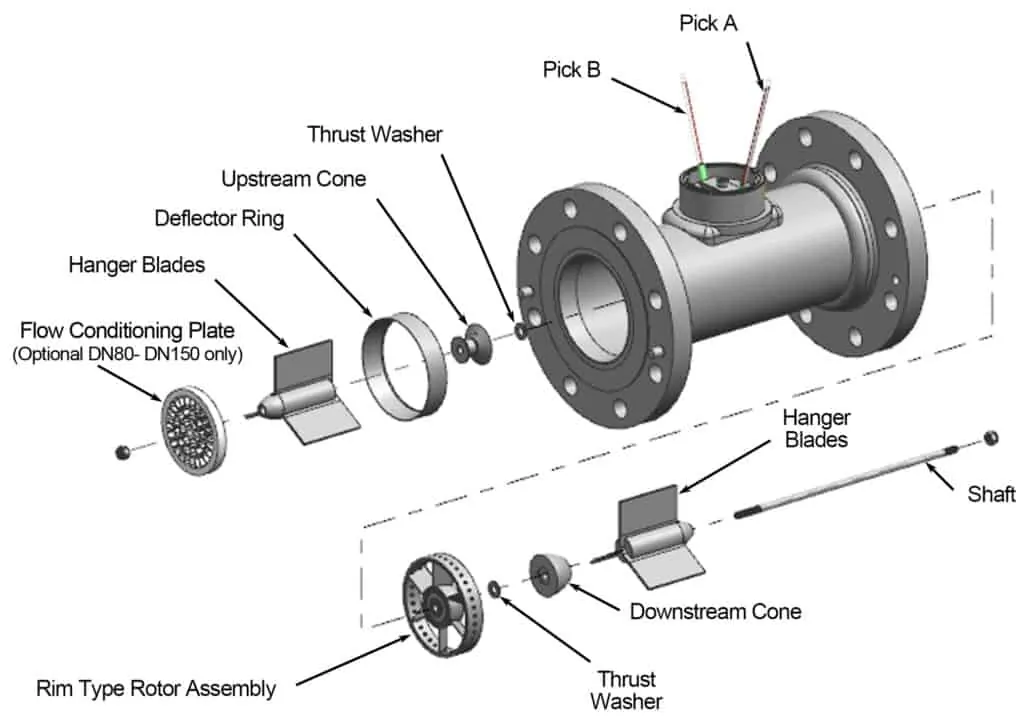

Turbine Flow Meter Working Principle

Gas turbine flow meter working principle

The gas turbine flowmeter uses a turbine for measurement. It first converts the flow rate into the rotational speed of the turbine, and then converts the rotational speed into an electrical signal proportional to the flow rate.

Gas turbine flowmeter is used to detect instantaneous flow and total integrated flow. Its output signal is frequency, which is easy to digitize.

The induction coil and the permanent magnet are fixed on the housing together. When the ferromagnetic turbine blade passes the magnet, the reluctance of the magnetic circuit changes, thereby generating an induction signal.

The signal is amplified and reshaped by the amplifier and sent to the counter or frequency meter. The total accumulated flow is displayed. At the same time, the pulse frequency undergoes frequency-voltage conversion to indicate instantaneous flow.

The speed of the impeller is proportional to the flow, and the number of revolutions of the impeller is proportional to the total amount of flow. The output of the turbine flowmeter is a frequency modulated signal. It not only improves the anti-interference of the detection circuit, but also simplifies the flow detection system.

The gas turbine flowmeter has a turndown ratio of up to 10:1, and the accuracy is within ±0.2%. The time constant of the turbine flowmeter with small inertia and small size can reach 0.01 second.

Extended reading: Quantitative control with turbine flowmeter

Liquid Turbine Flow Meter Working Principle

Liquid Turbine Flow Meter is a speed type flow meter based on the principle of torque balance.

The fluid flows through the sensor housing. Because the blades of the impeller have a certain angle with the flow direction. The impulse of the fluid makes the blades have a rotational torque. After the friction torque and fluid resistance are overcome, the blades rotate. The speed is stable after the torque is balanced.

Under certain conditions, the speed is proportional to the flow rate.

Due to the magnetic permeability of the blade, it is in the magnetic field of the signal detector (composed of permanent magnets and coils). The rotating blade cuts the magnetic lines of force. The magnetic flux of the coil is periodically changed. Electrical pulse signals are induced at both ends of the coil.

This signal is amplified and reshaped by an amplifier. A continuous rectangular pulse wave with a certain amplitude is formed. It can be transmitted to the display instrument remotely. The instantaneous flow or total amount of the fluid is displayed.

Within a certain flow range, the pulse frequency f is proportional to the instantaneous flow Q of the fluid flowing through the sensor. The flow equation is:

Where:

f——Pulse frequency [Hz]

k——The meter coefficient of the sensor [1/m3], which is given by the calibration sheet.

Q——The instantaneous flow of fluid (under working condition) [m3/h]

3600-conversion factor in seconds

The meter coefficient of each sensor is filled in the verification certificate by the manufacturer. The k value is set in the matching display instrument. The instantaneous flow and cumulative total can be displayed.

Extended reading: Turbine Flow meter Vs Gear Flow meter

Turbine flow meter Advantages and Disadvantages

Turbine Meter Advantages

- The cost is moderate.

- Very good at clean, low viscosity fluids of moderate velocity and a steady rate.

- Turndown is very good as it can read very low compared to the greatest flow.

- They are reliable if put in a clean fluid especially if it has some lubricity.

- AGA and API approved for custody transfers.

- They do cause some pressure drop where that may be a factor such as gravity flows.

- High accuracy. Among all flowmeters, it is the most accurate flowmeter.

- No zero drift, good anti-interference ability.

- High accuracy. Among all flowmeters, it is the most accurate flowmeter.

- No zero drift, good anti-interference ability.

Extended reading: Featured Cheap flow meters for Sale

Turbine Meter Disadvantages

- Not reliable for steam.

- Bearings wear out.

- Requires constant backpressure to prevent cavitation.

- Accuracy adversely affected by bubbles in liquids.

- Turbine meters can be used with clean liquids and gases only (may need to install a strainer upstream to prevent damage from particulates).

- Not applicable for measuring corrosive fluids.

- May not function properly with high viscosity fluids where the flow profile is laminar.

- Cannot maintain calibration characteristics for a long time.

Read more Turbine Flow Meter Application Case: Demineralized Water.

Industries and Applications We Serve

Mechanical Diesel Flow Meters for High Precision Measurement

High Pressure Flow Meters for Liquids-Steam-Gas

High Pressure Rotameter for Liquids/gas-Upto 25 Mpa

Turbine Flow Meter Installation Guidelines and Troubleshooting

Crude Oil Flow Meter

Guide for Digital Fuel Flow Meter

Explore Oil and Gas Flow Meters

Sino-Inst, Manufacuturer for Turbine Flow Meters, like: gas turbine flow meter, liquid turbine flow meter, sanitary turbine flow meter, insertion turbine flow meter, steam turbine flow meter, and natural gas turbine flow meter.

Sino-Inst’s Turbine Flow Meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.