Ultrasonic level sensor for diesel tank includes top mount and external mount. Oil tanks are storage equipment commonly used in oil depots, oil terminals, oilfield refineries and petrochemical enterprises. For the liquid medium (petrochemical products) in the tank, the liquid level, temperature, density and pressure (pressure storage tanks) are mainly measured. ) and other parameters. Calculate the volume and weight of the liquid storage.

Industrial diesel storage tanks are available in large and small tanks. Ultrasonic liquid level sensors can well meet the liquid level measurement of diesel tanks of various sizes and installation methods.

Featured Ultrasonic Level Sensor for Diesel Tanks

Challenges of Level Measurement in Industrial Diesel Tanks

Because the substances stored in diesel tanks are usually flammable, explosive, volatile, and toxic. In the event of leakage, accidents such as fire and explosion are likely to occur. Therefore, the general diesel tanks are divided into two categories: trade tanks and intermediate tanks.

The liquid level, temperature, density, volume, and mass of the trading tank must be monitored and measured frequently, and the accuracy is required.

Tundish tanks are usually only monitored for parameters such as level, temperature and pressure (pressurized storage tanks). In order to prevent the oil tank from roofing and evacuation accidents, it does not need to be handed over for measurement.

The selection of the diesel tank level sensor should be determined according to the design results of the oil tank. Different structures choose different liquid level instruments. Buried storage tanks and surface tanks, Ultrasonic Level Sensor for Diesel Tanks are cost-effective options.

Extended reading: fuel tank liquid level sensor 4-20ma

Features of Ultrasonic Fuel Level Sensors

Read more about: Ultrasonic VS Radar level transmitter-different applications

Ultrasonic Fuel Level Sensor Working Principle

Here we sort by where and how ultrasonic level sensors are installed.

The first type is the opening of the tank with the sensor mounted on the top.

The second type is that the tank body does not have holes, and the sensor is attached to the outer wall of the tank.

The third type is the sensor attached to the bottom of the tank.

Ultrasonic Fuel Level Sensors for Challenging Applications

Ultrasonic liquid level sensor is a liquid level sensor that is more commonly used to measure various material levels and liquid levels. It is divided into two types: integrated type and split type. Integrated ultrasonic level instrument, optional two-wire or four-wire system .The two-wire system can only supply 24VDC, 4-20mA current loop. Non-contact continuous measurement reduces maintenance and is cost-effective.

Extended Reading:

Laser Level Transmitter is a large-range, high-accuracy explosion-proof level measurement product supplied by Sino-Inst. It can measure media and application methods: particle, block, viscous, water conservancy, distance measurement, liquid level measurement, material level measurement

- The measured medium is flammable and explosive. Most of them are liquids and gases. For example: gasoline, alcohol, toluene, xylene, acetone, biogas, gas, hydrogen, etc., most of which are organic compounds. Solid: There are metal magnesium, metal sodium, yellow phosphorus, etc.

- Underground mines, including coal mines, iron ore, etc. Almost all mines require explosion-proof ultrasonic level sensors.

- Occasions with large dust. For example: wood processing workshop; coal processing workshop; when the dust reaches a certain concentration, it will also cause an explosion.

- Although there is no direct contact with flammable and explosive liquids and gases, it is also necessary to use explosion-proof ultrasonic level sensors and ultrasonic level sensors in explosion-proof areas. For example: fire pools in tank farms.

The above four situations require the installation of explosion-proof ultrasonic level sensors, which can avoid the existence of potential safety hazards.

Diesel Tank Level Monitoring System

The oil storage tank liquid level, temperature and pressure online monitoring system has changed the traditional method of using manual inspection ruler and laboratory analysis. Real-time dynamic monitoring of oil is realized. It provides accurate data basis for production operation and management decisions. Greatly avoid the occurrence of safety accidents.

All our level sensors support signal output. Including 4-20mA signal output. Or RS485 communication, etc.

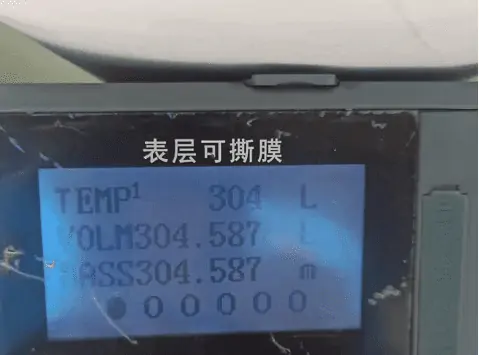

So, if you connect the output signals of all liquid level sensors to a multi-channel recorder. Our paperless recorder can display and record the liquid level of each tank.

Extended reading: More Inline Digital Diesel Fuel Flow Meters

Monitoring Liquid Volume Solutions

Most of our liquid level sensors can output liquid level signals, such as 4-20mA signal, 0-10V signal, RS485 and so on.

However, the liquid level transmitter alone cannot calculate the liquid volume of tanks of different sizes. It’s too complicated. A separate recorder is required to calculate it.

Therefore, the digital display volume meter can collect, display and convert the liquid level of various regular and irregular tanks in the industrial field into the corresponding tank volume. It is suitable for monitoring, controlling and collecting various process parameters.

Ultrasonic technology is not only used to measure level, but also can be used to measure depth. More about The Difference Between Ultrasonic Depth Sensor And Ultrasonic Level Sensor.

More Featured Diesel Tank Level Sensors

Frequently

Asked

Questions

More Featured Tank Level Measurement Solutions

Ultrasonic Fuel Level Sensor Price

Sino-Inst is Manufacturer of Ultrasonic Level Sensor for Diesel Tanks. We supply more than 20 kinds of Ultrasonic Level Sensor for Diesel Tanks. 40% ultrasonic level meters, 40% External Ultrasonic Liquid Level Meters and 20% Externally attached Ultrasonic oil level sensors.

Explosion-proof ultrasonic liquid level sensor reference wholesale price USD 285.00/pc

Ultrasonic Level Sensor for Diesel Tanks are mainly used for level measurement of various oils.

It can measure even liquids such as water, seawater, oil, and slurry.

Ultrasonic Level Sensor for Diesel Tanks enable stable level measurement without tank modifications. This greatly meets the measurement needs of many applications. Can be used from small to large tanks.

Sino-Inst’s Ultrasonic Level Sensor for Diesel Tanks, made in China, Having good Quality, With better price. Our level measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

The entire team at Sino-Inst’s has received excellent training, so we can ensure that every client’s needs are met. For assistance with your product requirements, whether it’s a Ultrasonic Level Sensor for Diesel Tanks, flow sensor, or other device, give us a call.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.