Ultrasonic Level Switch, External Mounted (referred to as “external level switch”) is a new type of level measurement alarm device.

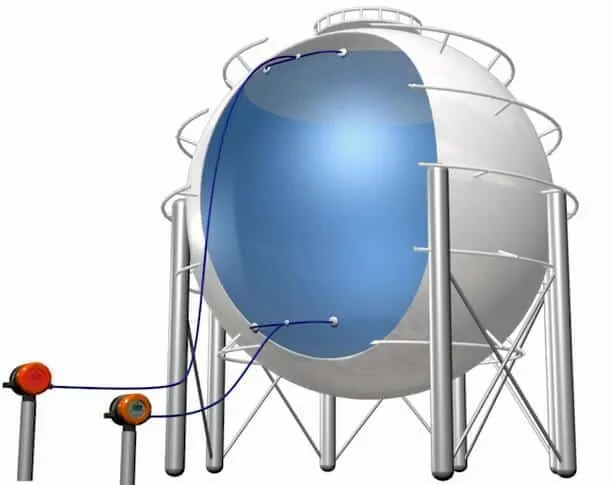

Ultrasonic Level Switch is mainly used to detect the liquid level of the storage tank. It can realize the upper and lower limit alarm or monitor whether there is liquid in the pipeline (dry protection). The material of the storage tank can be various metals, non-metals or non-foamed plastics. The wall thickness can be Up to 70mm.

Ultrasonic level switch is installed outside the tank. No need to open holes in the tank. Non-Contact Measure. The ideal choice for tank level monitoring.

Features of HS-ULC Ultrasonic Level Switch

- Wide range of applications. It can be used to measure various liquid media in highly toxic, corrosive, high-pressure, various complex working conditions, and explosive gas environments.

- The installation can be without stopping production, unclearing the tank, and keeping the fire. The installation is convenient and the operation is simple.

- The instrument works reliably and has stable performance. Strong anti-interference ability.

- The meter does not require user maintenance, maintenance-free. Long service life.

Specifications of HS-ULC Ultrasonic Level Switch

| Items | Values |

| Power Supply | DC 24V(18~36V) 0.05A |

| Repeatability error | ±2mm |

| Measurable tank type | Horizontal tank, spherical tank, vertical tank, etc. |

| Tank wall thickness | 2-70mm |

| Material | Cast aluminum |

| Electrical interface | Different types available for different operating condition |

| Time lag | 1-3 seconds |

| Explosion-proof Mark | ExdmIICT6 |

| Ingress Protection | IP65 |

| Output signal | Relay output (1 unit single-pole, double-throw control contact is passive nodes) |

| Relay capacity | DC 30V 6A / AC 250V 6A |

| Diameter of threading hole | Φ8mm ( adaptive cable diameter Φ6~8mm ) |

| Ambient temperature | -50℃~60℃ (-58 °F – 140 °F) |

| Ambient humidity | 15%~100%RH |

| Certificates | ISO SIL |

Extended reading: The Secret of Ultrasonic Level Measurement

Ultrasonic Level Switch Working Principle

The sensor of the external liquid level switch couples the generated high-frequency ultrasonic pulse to the container wall through the couplant.

The pulse will propagate in the container wall and liquid, and will be reflected by the inner surface of the container.

By detecting and calculating the characteristics of the reflected signal, it can be judged whether the liquid level has reached the position where the controller is installed.

The liquid level controller can output a relay signal to facilitate the detection and control of the liquid level.

Ultrasonic technology is not only used to measure level, but also can be used to measure depth.

Ultrasonic Liquid Level Switch Applications

Ultrasonic Level Switch is not affected by factors such as medium density, dielectric constant, conductivity, reflection coefficient, pressure, temperature, precipitation, etc. It is suitable for various liquid levels in the pharmaceutical, petroleum, chemical, electric power, food and other industries Engineering control. Ultrasonic Level Switch is the ideal choice for the detection of toxic, highly corrosive, and dangerous liquid level.

Applied Industries

- Petrochemical industry

- Chemical industry

- Foodstuffs

- Pharmaceutical industry

- Marine industry

- Oil refining industry

- Refrigeration industry

Applied Medium

| Liquefied Gas | Ethylene | Hydrochloric Acid | Nitric Acid | Sulfuric Acid |

| Propylene | Aqua Carbolisata | Edible Oil | Crude Oil | Lacquer Thinner |

| Brine | Butadiene | Chlorethylene | Light Hydrocarbon | Caustic Soda Liquid |

| Methylamine | Toluene | Light Oil | Gasoline | C3 |

| Kerosene | Xylol | Oxalic Acid | Oxirane | Acetone |

| Carbinol | Ethanol | Dimethyl Ether | Diethyl Ether | Diesel |

HS-ULC Ultrasonic Level Switch is specially used to measure the liquid level of tanks. Because it is installed on the outside of the tank, there is no need to punch holes, which is widely welcomed by customers.

Of course, if your tank already has holes, you can also choose other tank level transmitters.

Such as Liquid level float switch. Liquid level float switch is a commonly used liquid level controller. For water Tank & Pump alarm and level control. Can be divided into Continuous Float Level Sensor and Point Level Float Switch.

The ultrasonic principle can also be used to measure water depth. Please refer to Portable Ultrasonic Water Depth Gauge for water depth measurement.

Ultrasonic Level Sensor Working Principle

The working principle of the ultrasonic level senor: The high-frequency pulse sound wave emitted by the ultrasonic transducer is reflected on the surface of the measured level, and the reflected echo is received by the transducer and converted into an electrical signal. The propagation time of the sound wave is proportional to the distance from the sound wave to the surface of the object. The relationship between sound wave transmission distance S and sound speed C and sound transmission time T can be expressed by the formula: S=C×T/2.

Featured ultrasonic level sensors for tanks

Among various liquid storage tanks, ultrasonic level gauges are the most commonly used level gauges.

For open tanks, ultrasonic level sensors can be installed directly on the top of the tank.

For closed tanks, and an external ultrasonic sensor can be installed at the bottom.

Ultrasonic liquid level sensors use the propagation characteristics of waves in the medium. Ultrasonic transmitter and receiver can be installed at the bottom or top of the tank when measuring the tank liquid level. The emitted ultrasonic waves are reflected at the corresponding interface and received by the receiver. By measuring the time difference between the ultrasonic wave transmission and the reception, the liquid level can be measured.

Read more: Guide: Non-contact Ultrasonic Level Sensing transmitters

Float Level Sensors & Switches

The float level switch is a kind of level switch. The float level switch uses magnetic force to operate. No mechanical connections. The operation is simple and reliable. When the float switch floats the measured medium, the float moves the main body. At the same time, the magnet on the other end of the float will control the magnet on the switch action lever.

Frequently

Asked

Questions

Sino-Inst offers over 10 Ultrasonic Level Switches for level measurement. About 50% of these are fuel level meters, 40% is tank level sensor.

A wide variety of Ultrasonic Level Switches for level measurement options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Ultrasonic Tank Level measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.