Sludge level sensor is also called sludge level transmitter, sludge level detector, Online sludge interface instrument, or sludge blanket level detector. A sludge level sensor is an instrument used to measure the thickness of the mud layer in the liquid.

The sludge level can be expressed as the distance from the water surface (sludge level depth) or the distance from the bottom of the tank (sludge level height). Sludge level sensor is mostly used in the industrial process of solid-liquid separation. Continuously monitor the mud-water interface of sedimentation tanks or special thickening tanks. A sludge level sensor is an instrument commonly used in the sewage treatment industry (wastewater treatment plant) to monitor the sludge level/sludge bed level in the sedimentation tank or thickening tank.

What is a Sludge level sensor?

Sludge level sensor is an online water quality monitor with a microprocessor. The mud-water interface meter is an industrial online monitoring instrument designed to measure the treatment process of municipal sewage and industrial wastewater.

With the rapid economic development, industrial, agricultural and domestic water use is growing rapidly. More and more sewage is produced, and the problem has become increasingly serious. Therefore, to do a good job in sewage treatment can we ensure the recycling of water resources. In many industrial processes, suspended solids and liquids are separated by sedimentation. This process is usually completed in a sedimentation tank or a special thickening tank. And it is practical, and the mud-water interface must be continuously monitored.

A sludge level sensor is an instrument used to measure the accumulated thickness of sludge at the bottom of the sedimentation tank. It can enable the staff to clearly grasp the amount of sludge at the bottom of the tank at any time. The sludge discharge operation can be carried out in a timely and effective manner.

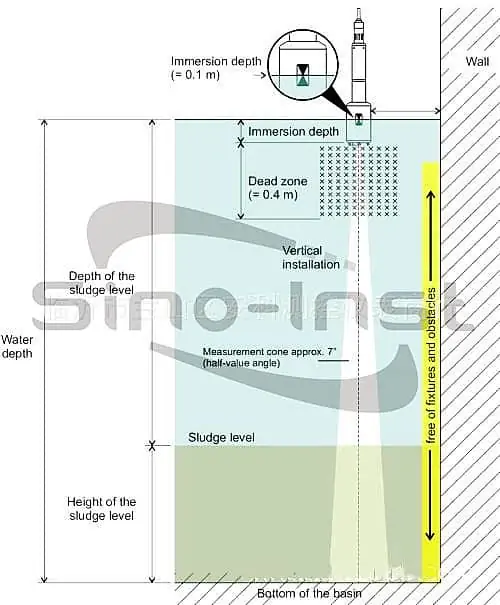

Ultrasonic Sludge level sensor is designed for long-term reliable operation in industrial and municipal fields. The sensor can work when it is immersed in water 5-10cm. The height of the sludge layer can be determined by ultrasonic emission and echo analysis of suspended solids in the water.

Using ultrasonic to accurately measure the height and thickness of the sludge layer. Effectively grasp the sludge sedimentation characteristics and control the return flow of the sludge. Let the operator make timely evaluations for optimizing the sludge circulation, compensating for the daily fluctuations of wastewater, correcting abnormal state values, and monitoring the separation layer in the pre-concentration tank. It also has a longitudinal profile graph that continuously displays the height of the sludge interface. It is helpful to understand the sludge settlement situation.

Extended reading: ultrasonic sludge level meter

Features of Ultrasonic Sludge level sensor

Specifications of Ultrasonic Sludge level sensor

1. Measuring range: 0.4~10 meters; 0.4-25 meters; or expand according to requirements;

2. Display mode: LCD

3. Unit of measurement: meter

4. Resolution: 0.01m

5. Accuracy: ±0.5 %FS

6. Repeatability: ±0.5%

7. Work rate: ≤3W

8. Ambient temperature: -20~50℃; relative humidity: not more than 90%

9. Analog output: two 4~20mA, load 750Ω

10. Switch output: three-way relay, capacity 250VAC/5A

11. Power supply: AC85~265V±10% or 9~36VDC

Application fields of Sludge level sensor

Sludge level sensor has strong practicability and convenient operation. It is an investment-efficient system for water and sewage treatment plants. Consistent sludge level monitoring data can directly improve the quality of the effluent. It can be widely used in sedimentation tanks of water plants and ore washing plants. Power mortar sedimentation tank. Primary sedimentation tank and secondary sedimentation tank of sewage treatment plant. Sludge interface monitoring fields such as thickening tanks and mortar sedimentation tanks in the power industry.

Read more about: Top 5 Ultrasonic Level Sensor Applications

Sludge level sensor Applications

First settling tank, second settling tank, gravity sedimentation tank;

Oil/asphalt separation tank;

Pulp pool

Waste treatment clarifier;

Beverage water clarification tank;

Mining clarifier;

Brine tank

Mud tank

Any container with a liquid/solid interface.

Extended reading: Case Study: Automatic Sludge Blanket Level Detector

Industry development prospects of Sludge level sensor

With the increasing development of domestic water environment management in recent years. The application range of the sludge interface instrument is still expanding. Under the strong attack of market opportunities, the Sludge level sensor market has ushered in another wave of development.

It is understood that the current monitoring of the mud level of sewage plants on the market mainly relies on manual labor. In addition to traditional visual inspection and water sample collection, there are also sludge interface meters or sludge concentration meters. But still, need a handheld instrument to collect and measure. These monitoring methods either require high manpower. Need real-time participation and poor timeliness. Either the monitoring has blind spots and the accuracy is not high. And it requires 24 hours of manual monitoring in the central control room.

In conclusion, in today’s development of the Internet of Things, machines are used to replace humans to achieve real-time and accurate monitoring. It not only brings great convenience to the development of environmental protection work. It also gives entrepreneurs the opportunity to enter the market. In the future, it is believed that with Sludge level sensor, fast, energy-saving, pollution-free, high selection, and other characteristics, it will serve more fields.

Extended reading: Capacitive water level sensor

Sludge blanket level detector working principle

Ultrasonic mud-water interface measurement uses an ultrasonic sensor installed in the water to emit an ultrasonic pulse to the surface of the mud underwater. This pulse signal is reflected back after encountering the muddy water surface. Can be received by the sensor again.

From the ultrasonic transmission to the re-reception. The time is proportional to the distance from the sensor to the surface of the object being measured.

The meter detects this time. And according to the current temperature (measured by the sensor) underwater sound speed. Calculate the distance from the surface of the measured object to the sensor (that is, the spatial distance). Further, convert the level value.

The empty underwater distance W on the surface of the liquid level is proportional to the travel time T of the sound wave: W=V×T/2 (where V is the speed of the sound wave in water).

The user sets the height H from the probe to the bottom of the pool. The instrument automatically converts the pulse travel time T into the corresponding space distance value W. Then calculate the difference of H minus W is the measured value L.

FAQ

More Wastewater treatment solutions

Sino-Inst offers over 10 Ultrasonic Sludge level sensors and transmitters for level measurement. 40% for wastewater treatment, 10% for Mud tank, others for more liquid/solid interface.

A wide variety of Ultrasonic Sludge level sensors and transmitters options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Ultrasonic Sludge level sensors and transmitters instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.