The VERIS Verabar Flow Meter, also called the Verabar Averaging Pitot Tubes, is a kind of differential pressure flow meter.

The SI-VL Verabar Flow Meter is designed with an aerodynamic engineering structure and is a sensor element. The VERIS Verabar Flow Meter is a plug-in flow meter. A Verabar tube sensor is inserted into the pipe. When the fluid flows through the sensor, a high-pressure distribution zone is created in the forward direction of the flow. And a low-pressure distribution zone is created in the rear. Verabar Flow Meter can be used to measure dry gas, humid gas, liquid or vapor, without being limited by dielectric constant.

Sino-Inst, Manufacturer for differential pressure flow meters. Including the Orifice plate, Venturi, Annubar, etc. Suitable for liquid, gas, and steam flow measurement. Please contact our sales engineers for technical support!

Features of VERIS Verabar Flow Meter

- The measure parts design base on-air dynamic principle

- The static pressure hole on the back side, produce the static pressure before split point between fluids and transducer, is the stable pulse signal

- Without removable parts, which can insure long term of the transducer, and also can insure long term stability, eliminate the precision drift

- Dust prevention. VERIS Verabar flow sensor is installed on both side of the transducer, not sensitive to medium particle and dust

- Uniform veloc

- ity tube flow sensor made of special material, in order to meet the demand of corrosive, high temperature, and pressure

- Easy to install;

SI-VL Verabar flow meter Specifications

- Applicable pressure: 0~30MPa

- Applicable temperature: -25 ~ +550 degrees

- Measurement accuracy: 1.5%

- Repeatability: 0.5%

- Sensor material: 304, 316L or special order

- Pipe size: DN38 ~ DN15000 round pipe or square pipe

- Turndown ratio: 10:1

- Flow range: the upper and lower limits of the measurement are at the probe strength and the minimum allowable differential pressure

Verabar flowmeter measures the required minimum flow rate and differential pressure

| Medium | Flow rate | Minimum differential pressure |

| Gas | 3.5m/s | 0.025kpa |

| Liquid | 0.6m/s | 0.25kpa |

| Steam | 9.0m/s | 0.38kpa |

VERIS Verabar flow sensors combined with Sino-Inst differential pressure transmitters. Provide the most reliable and accurate DP flow measurement solution on the market.

Differential pressure transmitter is a transmitter that measures the pressure difference between the two ends of the transmitter. The differential pressure transmitter outputs standard signals (eg 4 ~ 20mA, 0 ~ 5V). DP transmitters are different from pressure transmitters as they have 2 pressure interfaces. Differential pressure transmitters are generally divided into positive and negative pressure end. In general, the pressure at the positive end should be greater than the pressure in the negative section to measure. With flanges, capillaries, valve, brackets, throttle devices. Differential pressure transmitters are used to measure the level, density, and pressure of liquids, gases, and vapors. Then convert it into 4–20mADC current signal output.

Extended reading: [Working principle&Price]SI3051ANB Annubar Flow Meter

3-Types of Verabar Flowmeters

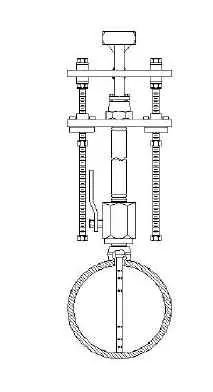

SI-VL200 verabar flow meter

The VL200 can be inserted and removed under pressure.

Use this model when you can not shut down the pipe to insert the sensor.

The VL200 is the most frequently sold hot-tap model.

It is available in single rod and double rod units for high pressure.

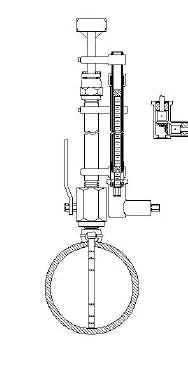

SI-VL350 verabar flow meter

The VL350 can be inserted and removed under pressure.

The insertion mechanism (Jack) can be removed and used on multiple pipes.

The Jack can be stored in a dry location away from the elements making it ideal for outdoor and coastal installations.

SI-VL400 verabar flow meter

The VL400 can be inserted and removed under pressure.

Similar to a VL200 except it has a flanged connection to the pipe for added sealing capability.

When plant regulations require a flanged hot tap connection, the VL400 is the correct model to use.

It is available in single rod and double rod units for high pressure.

VERIS Verabar Flow Meter Structure

The Verabar meter flowmeter consists of a detection rod, pressure tap, and a guide rod.

The cross-sectional shape of the detection tube of Verabar is divided into a variety of structures such as a circle,a diamond shape, and an elliptical shape.

What is Verabar Flow Meter?

The VERIS verabar flow meter is a high precision measuring instrument. Based on the principle of a piton tube measurement and applies the air dynamic theory.

Verabar flow meters belong to differential pressure flow meters, rate average of the flow sensor.

It measure flow rate through the differential, between average total pressure and static pressure, which often is used to measure the flow rate of the liquids, steam, and gas.

Extended reading: What Is A Venturi Flow Meter?

VERIS Verabar flow meter working principle

When the fluid flows through the probe, a high-pressure distribution zone is created at the front.

And the pressure in the high-pressure distribution zone is slightly higher than the static pressure of the pipeline.

According to the Bernoulli equation, the velocity of the fluid flowing through the probe is increased, and a low-pressure distribution zone is generated at the rear of the probe.

The pressure in the low-pressure distribution zone is slightly lower than the static pressure of the pipeline.

The fluid flows from the probe and creates a partial vacuum, at the back of the probe with vortices on either side of the probe.

The cross-sectional shape of the constant velocity flow probe, the rough surface condition and the position of the low-pressure tapping orifice are key factors, in determining probe performance.

The stability and accuracy of the low voltage signal are decisive for the accuracy, and performance of the uniform velocity probe.

The Verabar average velocity probe detects the average differential pressure produced, by the average velocity of the fluid.

The VERIS Verabar average velocity flow probe has multiple pairs of pressure tapping holes, arranged in certain directions in the high and low-pressure areas, which makes it possible to accurately measure the average flow rate.

Applications of Verabar Flow Meter

VERIS Verabar flowmeters are widely used in power plants, petrochemicals, metallurgy, water treatment, fine chemicals, environmental protection and other industries.

Verabar flowmeters are used in a wide range of applications for a wide range of gas, liquid and vapor measurements.

The following are typical application media.

- Water Treatment

- Pump Testing

- Paper & Pulp

- Effluent Treatment Plants

- Waste Water & Sewerage

- Food & Dairy Processing

- Chemical Process Plants

- Gas/Liquid/Steam;

- Natural Gas

- Cooling Water

- Saturated Steam;

- Compressed Air

- Boiler Water/Superheated Steam;

- Gas/Demineralized Water;

- Gas Hydrocarbon/Liquid Hydrocarbon;

- Hot Air/Cryogenic Liquid;

- Producer Gas/Thermal Liquid

You may like:

Sino-Inst offers over 10 VERIS Verabar flow meter products. These are differential pressure flow meters, 40% are water meters (like the Insertion Turbine Flow Meter), and 40% are water treatment (like the Annubar flow meter ).

A wide variety of VERIS Verabar flow meter options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of VERIS Verabar flow meter, located in China. The top supplying country is China (Mainland), which supply 100% of the VERIS Verabar flow meter respectively.

Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. VERIS Verabar flow meter products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.