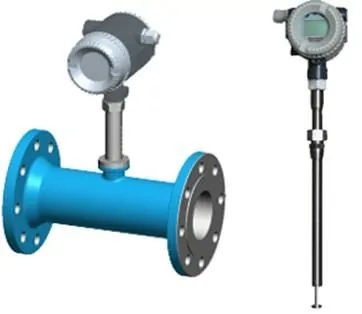

Compressed air flow meter is a upgraded and improved gas vortex flow meter. The karman vortex air flow sensor is researched and produced according to the Karman vortex principle.

Compressed air is an important energy source for manufacturing companies. Therefore, accurate measurement is of great significance to energy saving, emission reduction and cost accounting in the factory. Sino-Inst Vortex compressed air flowmeter is resistant to pipeline vibration. The value is not easy to jump randomly. An excellent partner for you to achieve accurate measurement. Integrated temperature and pressure compensation. The compensated instantaneous flow and cumulative flow can be read directly on the meter, Temperature, pressure and other data.

Vortex compressed flow meter reference price: USD 300-1500/pc.

Sino-Inst offers a variety of Vortex flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Features of Vortex Compressed Air Flow Meter

- Easy to install. Suitable for the measurement of compressed air, nitrogen, argon and other gases;

- Integrated temperature and pressure dual compensation. The instantaneous flow and accumulated flow, temperature, pressure and other data after compensation can be directly read on the meter head;

- The most advanced FFT spectrum analysis digital signal processing technology is adopted. The lower limit is low and the anti-vibration performance is excellent. It can be installed at the outlet of the air compressor to measure the air output of the air compressor;

- RS485 communication output. Equipped with related conversion modules, it can output wireless signals such as NB and GPRS, which can be used with the Internet of Things platform;

- Simple structure, no holes and gaps design. No wear, stain resistance, no moving parts. Low failure rate, high stability and reliability;

- The vortex flowmeter uses the latest signal processing technology, and the entire system analyzes the measured signal. Then eliminates external interference and media disturbance. Therefore, stable measurement can be achieved even in harsh process conditions;

- The piezoelectric element of the vortex flowmeter is embedded in the probe body. It does not touch the medium, and there is no filler inside. The pressure loss is small and the service life is long;

- The original signal formed by the vortex flowmeter. The output frequency and flow rate are linear. There is no zero drift problem.

Specifications of Vortex Compressed Air Flow Meter

| Measuring medium | compressed gas |

| Measuring range | See the flow range table of vortex flowmeter for details |

| 口 Path | DN15~DN600 |

| Connection method | Wafer type, flange type |

| Medium temperature (℃) | (-40~80)℃、(-40~400)℃ |

| Environment temperature (℃) | (-30~+65)℃ Atmospheric pressure: 86kPa~106kPa |

| Accuracy | 1.0%, 1.5% |

| Velocity range (m/s) | 1.5~60 |

| Output signal | 1: No local display frequency signal: high level≥5V low level 1V, square wave, pulse duty ratio: 1:1, emitter follower output (optional open collector output) 2: Standard current signal; (4-20) mA standard current signal proportional to the flow 3: Local display instantaneous flow, cumulative flowmeter. Simultaneously output proportional (4-20) mA standard current signal and pulse frequency signal or (4-20) mA+HART 4: Communication method: RS485 communication |

| Power supply | Voltage pulse type: DC12V, DC24V Standard current output, local display: DC24V Battery powered local display lithium battery: 3.6V |

| Ambient temperature | Ambient temperature (-40~+55) ℃, relative humidity 5~90 (%), atmospheric pressure: 86kPa~106kPa |

| Protection level | IP65 is used for indoor and outdoor installation, IP68 can be used for diving installation |

| Explosion-proof grade | Intrinsically safe Ex ia ⅡC T6 Ga |

| Show | Instantaneous standard flow, cumulative standard flow, pressure, temperature, instantaneous working condition flow, instantaneous cumulative flow, frequency |

| Cable interface | M20×1.5 (internal thread, recommended); 1/2NPT (internal thread) |

Extended Reading: Digital air flow meters

Compressed Air Flow Meter Working Principle

The vortex compressed air flowmeter is a volume flowmeter that measures the volume flow of gas, steam or liquid, the volume flow or mass flow of the standard condition according to the Karman vortex principle.

When a triangular cylindrical vortex generator is installed in the fluid, regular vortices are alternately generated from both sides of the vortex generator. This type of vortex is called Karman vortex. When the fluid passes through the vortex flow transmitter in the pipeline, two rows of vortices proportional to the flow velocity are alternately generated up and down behind the vortex generator of the triangular column. The release frequency of the vortex is related to the average velocity of the fluid flowing through the vortex generator and the characteristic width of the vortex generator.

The temperature compensation integrated vortex flowmeter also has a temperature sensor. The temperature of saturated steam can be directly measured and the pressure can be calculated. This shows the mass flow of saturated steam.

The temperature and pressure compensation integrated type is equipped with temperature and pressure sensors for gas flow measurement. The temperature and pressure of the gas medium can be directly measured to display the standard volume flow rate of the gas.

Read more about: Importance Of Air Flow Measurement

Compressed Air Flow Measurement

Compressed air is an important secondary energy source for industrial production. Most of it is converted from electrical or thermal energy through compressors. The working fluids converted from a large amount of energy are managed to achieve the effect of saving energy and improving equipment management. Compressed air It is an important economic indicator for cost accounting of enterprises and institutions. This is the main purpose of compressed air flow measurement.

Compressed air flow is an important parameter that expresses the performance of an air compressor, and it is also an important parameter measured in an industrial process. With the widespread application of air compressors, accurate measurement of its flow is essential for product upgrades, industrial production process control and monitoring, and energy conservation and emission reduction.

Compressed air has the following characteristics. Sino-Inst suggestion: Combine the characteristics of compressed air to make a reasonable selection of compressed air flow meters.

Large vibration

Of course, not every air flow meter is installed in places with high vibration. However, the air flow meters installed in the compression plant and the blower room have to consider vibration issues. This vibration mainly comes from compressors and blowers.

The vibration of the machine can be transmitted to a long distance through the air duct or duct. Among them, the largest vibration is the reciprocating compressor. The vibration generated during the operation of large reciprocating compressors often drives the workshop and the surrounding ground to vibrate together. It poses a threat to the accurate and reliable operation of related air flow meters. It causes the fulcrum of the lever-type differential pressure transmitter to move and causes the meter to drift in indication. Vibration causes the vortex flow sensor to produce an interference signal corresponding to the vibration frequency, causing the flow indication to be significantly higher.

Gas with water

Compressed air is taken from the atmosphere, and the atmosphere always contains a certain amount of water vapor. The content of water vapor is expressed by the partial pressure of water vapor ps.

In rainy and foggy days, the partial pressure of water vapor in the outdoor atmosphere reaches saturation. That is, the relative humidity reaches 100%. At this time, compressing the atmosphere is like compressing a sponge that absorbs enough water. As the volume shrinks, there is a corresponding amount Water precipitates. This is the simple principle of compressed air with water.

In fine weather, the relative humidity of the atmosphere is low. However, as it is compressed and reduced to a fraction of its original volume, the partial pressure of water vapor will increase accordingly, and it may also enter a saturated state and precipitate water droplets.

Large-caliber orifice flow meters used to measure the flow of compressed air often have water in front of the orifice, which will affect the accuracy of the measurement. There is often a section of water in the impulse pipeline, causing the differential pressure measured by the differential pressure transmitter to be inconsistent with the differential pressure produced by the throttling device. These are common causes of errors caused by water in the air.

In addition, due to the high nitrogen oxide content in the urban atmosphere, the water droplets contained in the compressed air are acidic, causing corrosion on the surface of the annular chamber and corrosion of the inner wall of the pipeline. The surface becomes rough.

When the iron oxide produced by corrosion becomes dry under certain conditions, it is easy to fall off from the inner wall of the pipe and be carried by the airflow to the front of the orifice plate. This will also affect the flow rate indication. Therefore, these powdery and massive garbage should be removed when the flow is stopped for maintenance.

Pulsating flow

Most of the compressor and blower outlet fluids contain certain pulsation. For example, a reciprocating compressor exhibits half-wave pulsation. Observed at the scene that the outlet pressure of the compressor and blower swings significantly.

Among them, the pulsation frequency of the outlet of the positive (constant) displacement blower is relatively high, generally tens of Hz. The pulsation frequency of the outlet of the reciprocating compressor is relatively low, generally a few hertz.

Flow arterial movement causes high indications of various flowmeters such as differential pressure flowmeters and vortex flowmeters. Cause the float in the float flowmeter to jump up and down.

There are two common methods to eliminate and weaken the influence of flow arterial movement on the value of the flow meter.

One is to install a buffer tank at the compressor outlet to filter out pulsation. Instead, install the flowmeter behind the buffer. In fact, the systems of reciprocating compressors are designed in this way.

The second is to install the flowmeter away from the source of pulsation. In this way, the gas capacity of the process pipeline and its pipe resistance can be used to form a low-pass filter to attenuate the pulsation.

Read more about: Rotameter flow meter-Variable Area Flow Meters. Suitable for liquid and gas volumetric flow measurement and control.

Is temperature and pressure compensation required for Compressed Air Flow Meter?

Many users encounter such troubles: I am measuring compressed air, do I need temperature and pressure compensation?

SIno-Inst relieves your worries:

Whether you need temperature and pressure compensation depends on your requirements for measurement accuracy.

If you have high requirements for measurement accuracy, temperature and pressure compensation is the most accurate.

If you are not demanding and want to save costs, and the pressure fluctuation is not large, you do not need temperature and pressure compensation.

Extended reading: Featured Cheap flow meters for Sale

More Featured Compressed Air Flow Meter

Sino-Instt offer over 10 Vortex Compressed Air Flow Meters, with Best Price.

A wide variety of Vortex Compressed Air Flow Meters options are available to you, such as free samples, paid samples. All of our flow meters can wokrk with the AMS NEW TREX.

About 13% of these are magnetic flow meter, 14% are Insertion Magnetic Flow Meter, 25% are Venturi flow meter, 13% are Handheld ultrasonic flow meter, and others are Liquid Turbine Flow Meters.

Sino-Inst is Vortex Compressed Air Flow Meterr suppliers, located in China. Vortex shedding flow meter products are most popular in North America, Mid East, and Eastern Europe.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.