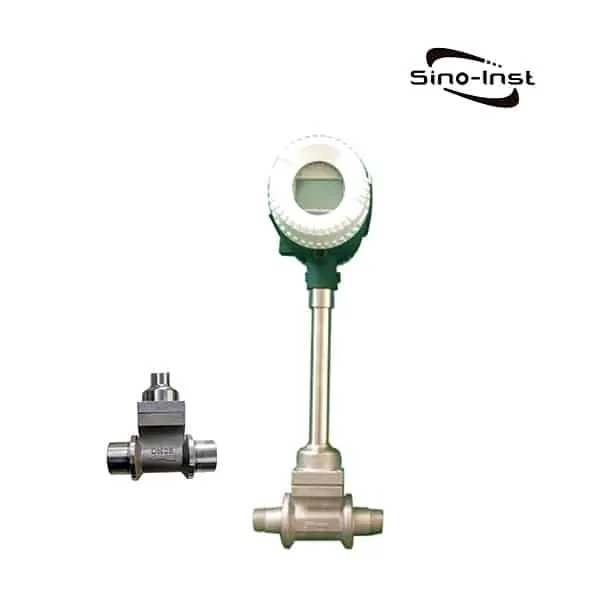

Vortex shedding flow meter, also called Vortex flow meter. Vortex shedding flow meter is suitable for measuring steam flow rate as well as liquids and gases.

Vortex shedding flow meter, easy installation, low cost, analog and 4-20mA output. Pressure & temperature compensation can improve the sensor for more accurate measurement. Vortex shedding flow meter is suitable for measuring steam and various liquids and gases. When the fluid flows through the assembly line of the vortex flowmeter, a vortex is formed. The frequency of vortex shedding is directly proportional to the fluid velocity.

Vortex shedding flow meter reference price: USD 200-1500/pc.

Sino-Inst offers a variety of Vortex flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Industrial Vortex Shedding Flow Meter Features

- Sonic nozzle calibration. High repeatability and high measurement accuracy

- Temperature compensation and pressure temperature can be freely selected. To meet more on-site use

- The circuit board is aging and running before leaving the factory. And the whole meter is calibrated one by one. It is more suitable for on-site use

- Wide application range. Gas, liquid and steam can be measured

- Low pressure loss. Low energy loss. Conducive to energy saving

- Simple and firm structure, no moving parts. High reliability and low maintenance

Specifications of Vortex Shedding Flow Meter

| Diameter(mm) | DN15,20,25,40,50,65,80,100,125,150,200,250,300,(300~1000 plug-in) |

| Nominal pressure(MPa) | DN15-DN200 4.0 (>4.0,Consulting supply) DN250-DN300 1.6(>1.6,Consulting supply) |

| Medium temperature(ºC) | Piezoelectric type :-40~150,-40~260,-40~330℃; Projected Capacitive:-40~400℃ (Consulting supply) |

| Body material | 1Cr18Ni9Ti (Other material order by Consulting supply) |

| Permissible vibration acceleration | Piezoelectric type :0.2g Projected Capacitive:1.0-2.0g |

| Accuracy | ±1%R,±1.5%R;plug-in:±2.5%R |

| Range of degrees | 1:6~1:25 |

| Power Supply | Sensor:DC+12V,DC+24V; Transmitter:DC+12V,DV+24V; Battery-powered:3.6V battery |

| Output signal | Pulse:high level:≥5V low level:≤1V; electricity current:4~20mA |

| Pressure loss coefficient | Comply with JB/T9249 standard Cd≤2.4 |

| Explosion-proof coefficient | Intrinsic safety :Ex ia II CT2-T4 Explosion-proof type:Exd II CT2-T5 |

| Level of protection | Ordinary type:IP65 Diving type:IP68 |

| Environmental conditions | Tempersature:-20ºC~55ºC, relative humidity 5%~90%, atmospheric pressure:86~106kPa |

| Applicable medium | gas ,liquid,steam |

| Transmission distance | Three-wire pulse output:≤300m, Two-wire standard current output:(4~20mA)≤1500m load resistance≤500Ω; RS485/HART≤1200m. |

Vortex Shedding Flow Meter Structure

The basic structure of LUGB series vortex flowmeter is shown in figure 1. It is mainly

composed of shell, vortex generator, flow sensor, temperature sensor, pressure sensor, shield bar,

integrator and other main accessories

- Integrating instrument

- Pressure transducer

- Shielding rod

- Shell

| Table of operating flow range of vortex street flow sensor under reference condition | ||||

| Diameter (mm) |

LIQUID | GAS | ||

| Range of measurements (m³/h) |

Output frequency range (Hz) |

Range of measurements (m³/h) |

Output frequency range (Hz) |

|

| 15 | 0.3~5 | 35~600 | 2.2~20 | 260~2000 |

| 20 | 0.6~10 | 29~420 | 4~36 | 210~1900 |

| 25 | 1.2~16 | 25~336 | 8.8~55 | 190~1140 |

| 32 | 1.8~20 | 18~264 | 10~150 | 156~1080 |

| 40 | 2~40 | 10~200 | 27~205 | 140~1040 |

| 50 | 3~60 | 8~160 | 35~380 | 94~1020 |

| 65 | 4~85 | 6~120 | 35~800 | 94~940 |

| 80 | 6.5~130 | 4.1~82 | 86~1100 | 55~690 |

| 100 | 15~220 | 4.7~69 | 133~1700 | 42~536 |

| 125 | 20~350 | 3.2~57 | 150~2000 | 38~475 |

| 150 | 30~450 | 2.8~43 | 347~4000 | 33~380 |

| 200 | 45~800 | 2~31 | 560~8000 | 22~315 |

| 250 | 65~1250 | 1.5~25 | 890~11000 | 18~221 |

| 300 | 95~2000 | 1.2~24 | 1360~18000 | 16~213 |

| -300 | 100~1500 | 5.5~87 | 1560~15600 | 85~880 |

| -400 | 180~3000 | 5.6~87 | 2750~27000 | 85~880 |

| -500 | 300~4500 | 5.6~88 | 4300~43000 | 85~880 |

| -600 | 450~6500 | 5.7~89 | 6100~61000 | 85~880 |

| -800 | 750~10000 | 5.7~88 | 11000~110000 | 85~880 |

| -1000 | 1200~1700 | 5.5~88 | 17000~170000 | 85~880 |

| >(100) | Consulting supply | Consulting supply | ||

Vortex Shedding Flow Meter Working Principle

Vortex flowmeter is a speed-type flowmeter produced according to karman’s vortex principle,

which can be used for the measurement and measurement of conventional gas, steam and

liquid.

Vortex flow sensor has high precision and wide range ratio, no moving parts in use, which can

improve mechanical stability and reduce maintenance.Vortex flowmeter is almost not affected by the temperature, pressure and composition of medium when measuring the volume of working condition.

Therefore, it is convenient to calibrate the instrument, so vortex street flow sensor is widely used in production and life.

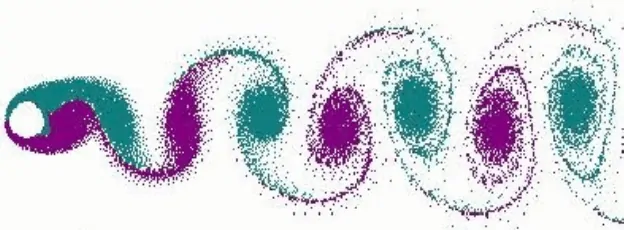

When a trigonal column vortex generator is set in the fluid, regular vortices are generated alternately on both sides of the vortex generator, which is called Carmen vortex.

The vortex columns are arranged asymmetrically downstream of the vortex generator. Vortex flowmeter is produced according to this principle.

Vortexes are generated by generating bodies and the number of vortexes is detected by high-sensitivity sensors. In a certain range, the number of vortexes generated is proportional to the flow rate.

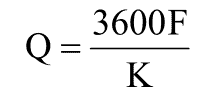

In vortex flowmeter, the relationship between flow rate and the number of vortexes generated

can be expressed by the following formula:

Q:Operating volume flow of the measured medium. The unit is m3/h。

F:Frequency of the number of vortices produced by the generating body. The unit is Hz.

K:Refers to the calculated or calibrated flow coefficient. It represents how many frequency signals per cube. the coefficient is usually obtained by calibration.

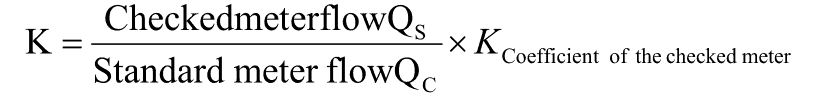

The formula of standard table method calibration coefficient K:

The formula can also be used for flow correction.

Applications of Vortex Shedding Flow Meter

Steam Flow Measurement

Steam has often been described as the ‘lifeblood’ of the industry.

Vortex meters are known to be superior devices for steam flow measurement, due to their inherent linear measurement, large turndown, low-pressure drop, and high accuracy.

The vortex flowmeter is ideal for high temperature, superheated, and saturated steam applications, since it eliminates the need for separate components and associated installation temperature.

In addition, it provides quality, dependability and high-pressure ratings,along with a stable and reliable flow measurement.

Read more about: Steam Flow Measurement: Do you need temperature and pressure

Liquid Applications

Liquid applications in the oil refinery industry become challenging, since the process liquid is a higher viscosity at lower process temperatures.

As a result, clogging becomes an issue when a flow meter has moving parts.

Sino-Instrument vortex meters have advanced self-diagnostics, that alert the operator if clogging or plugging in the area around the shedder bar are present.

Alerts are also triggered in high-vibration environments and those with excessive flow fluctuations in the area around the shedder bar. This enables automatic condition-based maintenance.

Extended reading: Integral DP Flow Meter|Gas, liquid, steam|Compact structure

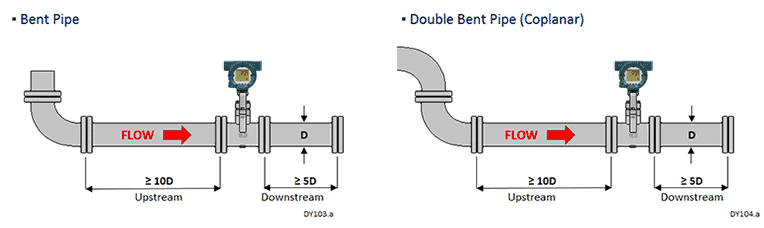

Installation for Industrial Vortex Flow Meter

Know more about vortex shedding flow meter:

More industrial vortex flow meters:

Sino-Instt offer over 10 Vortex Shedding flow meters, with Best Price.

A wide variety of industrial Vortex shedding flow meters options are available to you, such as free samples, paid samples. All of our flow meters can wokrk with the AMS NEW TREX.

About 13% of these are magnetic flow meter, 14% are Insertion Magnetic Flow Meter, 25% are Venturi flow meter, 13% are Handheld ultrasonic flow meter, and others are Liquid Turbine Flow Meters.

Sino-Inst is Vortex shedding flow meter suppliers, located in China. Vortex shedding flow meter products are most popular in North America, Mid East, and Eastern Europe.

The United States, and India, which export 99%, 1%, and 1% of ultrasonic level transmitter respectively. You can ensure product safety by selecting from a certified supplier, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.