Wastewater level sensor occupies a large proportion in sewage treatment applications. It is used in almost all aspects of sewage treatment. In sewage treatment, the level of waste water, sludge, chemical solutions, etc. needs to be measured. Sewage lift station and wastewater treatment plant often use radar, ultrasonic, pressure sensor, etc. To monitor the liquid level.

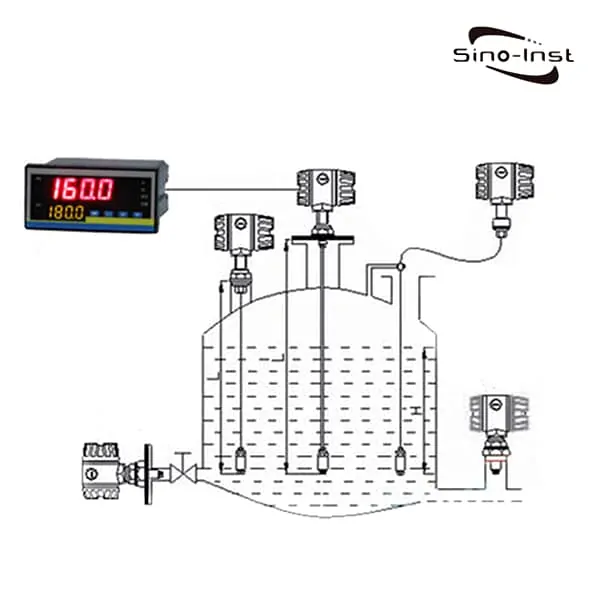

In the sewage treatment system using automatic control. The wastewater level sensor is used to measure the liquid level. Many also involve the start and stop of interlocking pumps and the opening and closing of control valves in automatic control.

The following combined process analysis, the selection of wastewater level sensor.

Featured Wastewater Level Sensors

Selection of Level Sensors for Wastewater Treatment

Sewage treatment projects involve the measurement of various process parameters such as liquid level (difference), flow, pressure, temperature, concentration (including PH, dissolved oxygen, etc.), turbidity and so on.

Because the process of sewage treatment involves many occasions that need to measure the liquid level. Also because of the characteristics of the process of sewage treatment itself. In the selection process, it is necessary to select a suitable level gauge according to the characteristics of each process and medium. It will have a great impact on the accuracy, reliability and stability of process measurement and economic life.

It is recommended to choose a level gauge with high accuracy, low maintenance, and long service life as far as possible when the budget permits. The liquid level measurement and control of the entire sewage treatment can be operated reliably, stably and safely.

Pay attention to the following points when selecting Level Sensor

- Measurement object. Such as the physical and chemical properties of the measured medium. As well as working pressure and temperature, installation conditions, the speed of liquid level changes, etc.;

- The sensor must be able to measure sewage. The acid, alkali and small particles in the sewage have no influence on its measurement accuracy and life.

- The sensor has high measurement accuracy, easy to install and easy to adjust.

- The Level Sensor display is intuitive and has analog output and alarm output functions.

- Measurement and control requirements. Such as measuring range. Measurement (or control) accuracy. On-site instructions, remote instructions. The interface with the computer. Safe anti-corrosion. Reliability and ease of construction.

Extended reading: sludge blanket level detector

Wastewater Level Sensors Types

In sewage treatment, the level of waste water, sludge, chemical solutions, etc. needs to be measured. In the sewage treatment system using automatic control. The Level Sensor is used to measure liquid level. Many also involve the start and stop of interlocking pumps and the opening and closing of control valves in automatic control.

Compared with other types of measuring instruments, there are many types of level gauges suitable for sewage treatment projects. There are two types of contact and non-contact measurement.

All of the above must be considered. Pay attention to the physical and chemical properties of different measured liquids according to different types of Level Sensors.

The following will analyze the selection of the sewage treatment Level Sensor according to the combined process.

About Water Level Sensor Types and how they work. OMEGA Engineering has a good introduction video. Let’s take a look.

Ultrasonic Septic Tank Sensor

Septic tank ultrasonic level meter is used as an instrument to intelligently detect the height of the septic tank. Played a vital role in the maintenance of public toilets.

In the previous toilet maintenance, the manure trucks were cleaned regularly and fixedly. Doing so will inevitably cause some waste of resources.

Install septic tank ultrasonic level gauges in public toilets. The liquid level of the manure tank can be monitored in real time. It will automatically alarm when it reaches a certain height. The transmission system is connected to the control center. The front calls the police and the rear supports.

This can greatly save manpower and material resources. It is of great significance for energy saving, environmental protection and resource saving.

Septic tank ultrasonic level meter needs to be equipped with automatic alarm device or SMS alarm device. Ultrasonic module with 485 communication is used for liquid level monitoring. And through multiple communication modules with 485, the liquid level is monitored uniformly by the unified terminal system. This can not only display in real time. It is also possible to remind the user management personnel through a text message reminder or terminal alarm device when the septic tank is almost full.

Septic Tank Alarm Float Switch

The float level switch is specially used for liquid level detection of various medium and small normal pressure and pressure liquid storage tanks, remote transmission of on-site indicator signals, and liquid level alarm. It can be applied to various sanitary, toxic, corrosive media and explosive gas dangerous places. There are also many types of installation. Suitable for various forms of containers.

External Tank Level Indicator

The external tank level indicator is a new type of non-intrusive ultrasonic level measurement system. This is a real non-invasive, non-contact measurement method.

Just install the measuring probe on the outer wall of the bottom of the tank or container. The reflection and transmission characteristics of ultrasonic waves are used to realize the measurement of the liquid level inside the storage tank.

The calculated liquid level value is displayed locally, and a remote signal is output. The meter can output the measurement result to the control system through 4-20 mA analog signal, HART, RS-485 and other interfaces. At the same time, data can also be sent to the Internet via wireless transmission via WIFI, GPRS and NBIOT.

When the ultrasonic wave emitted by the probe propagates to the inner wall of the bottom of the container. The first reflected echo is generated due to the change of the propagation medium. After that, the ultrasonic wave continues to propagate in the measured liquid medium. When propagating to the gas-liquid interface, the propagation medium changes again. Produce a second reflection echo.

Assume that the time difference between the first reflected echo and the second reflected echo is T. According to the propagation speed c of the ultrasonic wave in the measured liquid. The liquid level value L =c*T/2 can be obtained in the container.

The advantage of this liquid level measurement method is that there is no need to open holes or install flanges for the container to be tested. The internal liquid level information can be obtained directly from the outside of the container. The non-intrusive liquid level measurement is truly realized.

Marine Holding Tank Level Indicator

Portable ultrasonic liquid level indicator is best choice for tanks or pipes level measurement. It is designed to measure the presence or absence of liquid at a certain height position in a tank or in pipelines. Non-contact ultrasonic detection technology. SI-ML works perfect for detection of dangerous toxic or corrosive liquids. Under ordinary conditions, the maximum wall thickness of measurable containers is 30mm. The product is suitable for the detection of various types of liquids. Liquids are non-crystalline or other particulate matter. For example CO2 Tank. Thanks to non-contact detection technology, this level indicator is ideal for detecting hazardous toxic or corrosive liquids.

How to Measure Ground Water Level ?

Dynamic monitoring of groundwater level:

It is advisable to use existing water wells, natural outcrops of groundwater, or drilling and exploratory wells in the project. When the borehole is easy to be blocked, a filter can be installed in the borehole for monitoring.

Deep Well water level sensor is to apply Hydrostatic Level Sensor to deep well. Well water level sensor submerged in deep well work together with submersible water pump. Range within 300m ~ 1000m.

The groundwater level online monitoring system is widely used in underground water deep well water level measurement, mine water level gauge deep well measurement, and geothermal well water level measurement.

The groundwater level online monitoring system is based on the principle of hydrostatic pressure in which the pressure is proportional to the water depth. The water pressure sensitive integrated components are used as the sensor probe of the deep well water level measuring instrument.

When the sensor probe is fixed at a certain measuring point underwater. The height of the water column pressure above the measuring point plus the height of the point. The water level (the distance from the water surface to the wellhead) can be measured indirectly. The direct measurement is above the sensor probe The actual height of the liquid level in the deep well.

FOGRod

The FOGRod is a wastewater level sensor manufactured by Wastewater Level. Unlike most level sensors it has no moving parts, sensors or electronics in the wet well.

The FOGRod hangs in a wet well much like a float switch or ultrasonic transducer and connects to a Level Indicator Transducer (LIT) which mounts in your control panel. The LIT has 10 relays that correspond to 10 contacts on the FOGRod.

Frequently

Asked

Questions

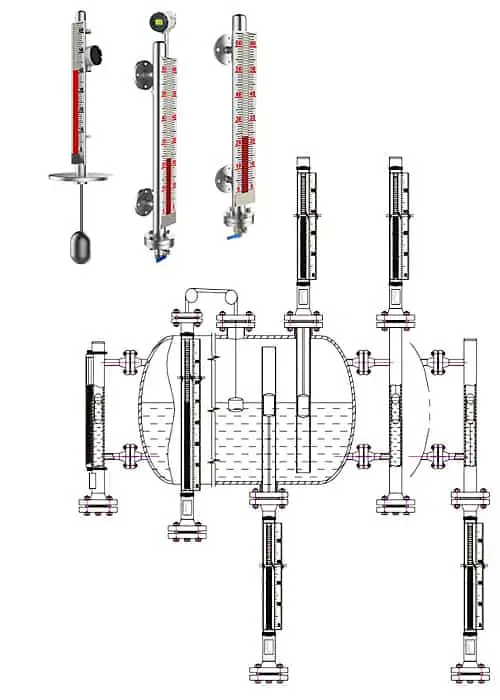

Sino-Inst offers over 50 Wastewater Level Sensors/Systems for Sewage-Wastewater. About 50% of these are Radar level meters, 40% is magnetic level sensor.

A wide variety of Wastewater Level Sensors for Sewage-Wastewater options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Wastewater Level Sensor/System for Sewage-Wastewater instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.