The water tank level sensor is an integral part of the water level monitoring and control system. They are responsible for real-time detection and feedback of the water level in the water tank. Water tank level sensors, solenoid valves, control boxes, liquid level switches and other accessories can be used to effectively form a water Level Monitoring & Control System. For example, in scenarios such as sewage treatment, drinking water storage and agricultural irrigation, the water pump switch can be automatically adjusted to control the Water intake and drainage to ensure stable water levels. Therefore, selecting an appropriate tank level sensor is a fundamental and critical task for any system that requires accurate water level monitoring.

Water Tank Level Monitoring and Control Systems

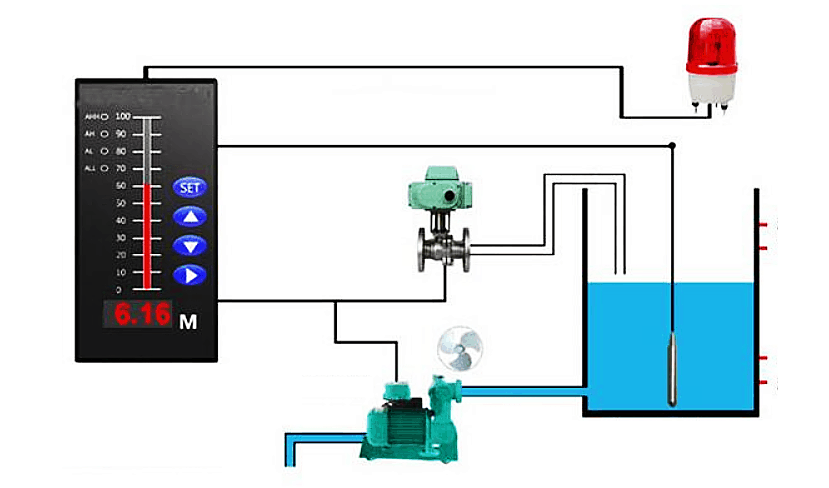

Water Tank Level Monitoring and Control Systems are a sophisticated set of technical devices used to track and manage water levels in water tanks in real time. Such systems typically include key components such as level sensors, controllers, displays, and actuators (such as pumps or valves).

- Water Tank Level sensors are the core of the system, responsible for measuring and transmitting water level data. These sensors can be of various types such as float type, pressure type, ultrasonic type, capacitive type, etc., selected according to different application scenarios. They convert water level changes into electrical signals and send them to the controller in real time.

- The controller is the brain of the system. It receives signals from the sensors and makes judgments based on the preset water level range. For example, when the water level is below the minimum limit, the controller will start the water pump to fill the water. When the water level reaches the maximum limit, the water pump will be stopped or the drainage valve will be opened to avoid overflow.

- The display provides the operator with an intuitive interface showing current water levels, as well as system status and alarm information. This information helps operators understand whether the system is functioning properly or if manual intervention is required.

- Finally, actuators, such as pumps and valves, are the actual devices that respond to controller commands and are responsible for physically regulating the flow of water. The system can automatically or manually adjust these mechanisms as needed to maintain water level stability.

Therefore, with Water Tank Level Monitoring and Control Systems, automatic management and control of water tank level can be achieved.

When the water level of the water tank drops to the set lower limit water level value, the liquid level controller sends a command to instruct the pump valve to open the water supply.

When the water level reaches the set upper limit water level value, the controller will issue an instruction to instruct the pump valve to close and stop the water supply.

In the same way, if necessary, the liquid level controller can also instruct the water pump or electric valve to perform the opposite operation.

Extended reading: Magnetostrictive Hydraulic Cylinder Position Sensor

Extended Reading: How to Measure Volume of Liquid

Water Tank Level Sensors Types

The water tank level sensor is a key device to ensure the accuracy of water level monitoring. According to their working principles and application environments, they can be mainly divided into the following types:

Comparison of digital sensors and traditional mechanical sensors:

Digital level sensor: Using advanced electronic technology, it can provide continuous, high-precision water level readings. And it can be seamlessly integrated with computer systems to facilitate remote monitoring and data analysis. They generally have better long-term stability and immunity to interference.

Traditional mechanical level sensors: usually refer to float sensors, which sense water level changes through a simple mechanical structure. Although these sensors are simple and low-cost, they are often less accurate than digital sensors and are susceptible to mechanical wear and water quality.

When selecting a water tank level sensor, it is important to select the most appropriate type based on factors such as the actual application environment, accuracy requirements, and whether remote monitoring is required.

Extended reading: Industrial Tank level indicators and Tank Level Gauges

We, Sino-Inst, are a professional manufacturer of Water Tank Level Sensors. Provide users with more than 50 types of Water Tank Level Sensors and switches.

Featured Water Tank Level Sensors

PLC liquid level display alarm

Programmable Logic Controller, PLC for short. A digital electronic device with a microprocessor. A digital logic controller used for automatic control. Control instructions can be loaded into the memory for storage and operation at any time.

The programmable controller is modularized by internal CPU, instruction and data memory, input and output unit, power supply module, digital-analog, and other units.

PLC can receive (input) and send (output) many types of electrical or electronic signals. And use them to control or supervise almost all types of mechanical and electrical systems.

Extended reading: ultrasonic level sensor for diesel tank

Program through the PLC system to realize the automatic level control system. It is composed of hardware and software. The hardware mainly includes PLC touch screens and related modules such as CPU, storage, output and input, power supply. On-site measurement includes various types of adaptation to different sites Conditional sensors, switches, etc. Also include sound and light warning lights, control buttons, and other related equipment.

By configuring the PLC liquid level display alarm device, it can realize the display of industrial site liquid level measurement, high and low liquid level alarms. As well as the opening and closing of pumps, valves, and other equipment. Unattended automatic workflow can be realized. Greatly improve production The efficiency, saving human cost. This brings about an increase in corporate benefits. It lays the foundation for the company to take the lead in severe competition in the future.

Therefore, in the current situation, whether it is a newly established project or a modified project, it is recommended that PLC equipment is the first choice when conditions permit.

Extended reading: Magnetostrictive Hydraulic Cylinder Position Sensor

Extended Reading: How many types of level transmitters are there?

Wireless water tank level sensor-Future Trends

Wireless GPRS liquid level alarm device, can be configured with eight channel alarm device, liquid level display alarm device, LED display. It can support liquid level meter switch, float level switch, pressure transmitter, thermocouple, thermal resistance, voltage, Current and transmitter input. Suitable for monitoring of industrial process quantities such as temperature, pressure, flow, and liquid level.

Construction-free installation: It can replace the connecting cable, and the transmission distance is long, eliminating the trouble of cable construction.

Support 8-channel alarm function, power supply 220VAC or 24VDC switching power supply. For explosion-proof occasions, explosion-proof sensors and explosion-proof instrument boxes can be used.

On-site measurement end. Configuration:

- Level gauge (can be equipped with level gauge, pressure gauge, temperature gauge)

- Signal acquisition instrument meter box (common type and explosion-proof type are optional)

- The switch quantity acquisition module is included in the instrument box

- DTU module in the instrument box

Extended reading: Ultrasonic Level Switch-External Mounted

FAQ

How to choose right Water Tank Level Sensor for your System

When selecting a tank level sensor and monitoring system, you need to consider the following specific recommendations and reference values:

Application Environment:

- Water quality: If the water contains corrosive chemicals, sensors made of corrosion-resistant materials should be selected.

- Temperature: Make sure the sensor’s operating temperature range covers your application environment, such as -20°C to 80°C. If 80°C~150°C, you can refer to high temperature level sensors.

- Pressure: If used in deep wells, the sensor should be able to withstand a pressure of at least 2MPa.

Accuracy requirements:

- If the water level needs to be accurately controlled (error range ±1mm), high-precision sensors such as ultrasonic or capacitive sensors should be used.

- For general agricultural irrigation systems, the error range can be relaxed to ±5mm.

Installation and maintenance:

- Choose a sensor that is easy to install and configured with appropriate mounting dimensions. Such as threads, flanges, clamps, etc.

- Maintenance frequency: Choose sensors with high reliability (such as MTBF (mean time between failures) greater than 100,000 hours) to reduce the number of maintenance times.

Ease of use:

The user interface should have clear numerical or graphical displays to ensure easy operation.

Integration and Compatibility:

Choose sensors that support standard signal output and communication protocols (such as 4-20 mA, 0-10V, Modbus, etc.) to ensure compatibility with remote monitoring systems.

Budget and Cost Effectiveness:

- Calculate the total cost of ownership, including purchase, installation, scheduled maintenance and potential breakdown repairs.

- Consider sensors with energy-saving features, such as low-energy designs (power consumption less than 0.5W) to reduce operating costs.

Supplier technical support and services:

Choose sensors that offer at least a one-year warranty, and make sure the supplier has service points in the country for quick response.

By considering the specific recommendations and reference values above, you can select a tank level sensor and monitoring system that meets your technical requirements while being cost-effective.

More level monitoring solution

Extended reading: Fuel-Diesel-Water Tank Level Sensor Monitoring

When choosing a suitable water tank level sensor and monitoring system, we must consider a variety of factors, such as application environment, accuracy requirements, ease of installation and maintenance, and budget.

At the same time, we also provide other types of measuring instruments, such as wastewater flow measurement, liquid level measurement and pressure measurement equipment. These high-quality instruments can help you build a more comprehensive monitoring system.

Our Sino-Inst offers over 20 Water Tank Level Sensors for level measurement. About 50% of these are liquid level meters, 40% is the tank level sensor. A wide variety of Water Tank Level Sensors options are available to you, such as free samples, paid samples.

We offer a variety of measurement solutions and support customization to meet your specific needs. If you need professional advice or customized services, please contact us!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.