Dew point monitors are critical equipment in many industries. The dew point is the temperature at which the air humidity reaches saturation. A dew point monitor is the instrument that detects this temperature. Although dew point measurement is most often cited in weather forecasting, it is also an important factor in many industrial processes. Excessive moisture may impair product quality and performance as well as materials.

What is a Dew Point Monitor?

Dew point monitors are vital pieces of equipment used to measure the temperature at which the air becomes saturated, causing water vapor to condense into liquid. This temperature is known as the dew point. By monitoring this, we gain essential information about the humidity in a certain environment.

Why is this important? In many industries, excess moisture can pose significant problems. For example, in compressed air systems, high humidity can lead to corrosion in the pipelines. In the electronics industry, too much moisture can damage sensitive components. Similarly, in climate-controlled environments like laboratories, an accurate reading of the dew point is crucial for maintaining ideal conditions.

In essence, a dew point monitor gives us a precise, reliable way to keep track of humidity levels. By doing so, it helps prevent potential issues caused by moisture, ensuring everything runs smoothly in various environments where humidity control is critical.

how a dew point monitor works?

A dew point monitor works by examining the air or gas in an environment to determine the temperature at which it would be fully saturated, or, in other words, the temperature at which dew would form. This process might sound complex, but let’s simplify it a bit.

Picture a cool glass on a hot day. After a while, you’ll see droplets form on the outside of the glass. That’s condensation, which happens when the air around the cold glass cools down to a point where it can’t hold all its moisture. That exact temperature is the dew point.

Dew point monitors utilize advanced sensors to mimic this process. They chill a surface within the device and measure the temperature at which condensation begins to form on that surface. This temperature is reported as the dew point.

In short, dew point monitors give us an accurate way to measure the moisture content in the air, helping various industries prevent potential issues and maintain optimal conditions.

Technical Benefits of Dew Point Monitors

- Precision: Dew point monitors offer highly accurate measurements of humidity levels, which is critical for many industrial and commercial operations.

- Reliability: These devices provide reliable, consistent readings over time, supporting effective long-term humidity management.

- Versatility: With the ability to operate across a wide range of temperatures and humidity levels, dew point monitors are useful in numerous industries and settings.

- Preventive Maintenance: Dew point monitors facilitate timely interventions to avoid issues caused by excessive humidity, such as corrosion or equipment damage, leading to reduced maintenance costs and prolonged equipment lifespan.

- Product Quality Enhancement: By controlling dew point, these monitors can directly improve the quality of products in various manufacturing settings, from food packaging to electronics storage.

- Energy Efficiency: Especially in systems like compressed air dryers, dew point monitors help to regulate energy usage, thereby enhancing efficiency and reducing operational costs.

So, when we consider these substantial technical benefits, it becomes clear that dew point monitors play a vital role in managing optimal environmental conditions across a range of applications.

different industrial applications

Monitoring dew point is crucial across a variety of industries due to its impact on processes, product quality, and energy efficiency. Dew point monitors play a central role in this endeavor. Let’s delve into a few specific industries and applications:

HVAC and Building Management: In this field, dew point monitoring helps maintain comfortable and healthy indoor air quality. It also prevents condensation on surfaces, which can lead to mold growth and structural damage.

Pharmaceuticals and Healthcare: In pharmaceutical manufacturing and storage, maintaining a precise humidity level is critical to product quality and safety. Dew point monitors aid in ensuring these stringent conditions are met consistently.

Food and Beverage Industry: Here, dew point monitoring helps prevent condensation on machinery and packaging. This reduces the risk of microbial growth, ensuring the hygienic handling and quality of food products.

Electronics Manufacturing: In the production and storage of electronic components, maintaining a low dew point prevents moisture-related damage and improves product lifespan and reliability.

Compressed Air Systems: Dew point monitors ensure that the air used in these systems is dry enough to prevent pipeline corrosion and blockages from ice or condensed water.

Petrochemicals and Natural Gas: For these industries, dew point monitoring is critical for process control and safety, as excess moisture can lead to pipeline corrosion and efficiency loss.

In conclusion, the role of dew point monitors extends far beyond simple humidity measurement. They provide an essential service to a variety of industries, ensuring product quality, process efficiency, and operational safety. The right dew point monitoring can indeed make a significant difference in your industry or application.

How to Choose a Dew Point Monitor

Choosing a dew point monitor can feel like a daunting task, but with the right approach, it can be made simpler. Here’s a step-by-step guide to help you make the right decision:

- Understand Your Needs: The first step is understanding your specific requirements. What range of temperatures and humidity levels do you need to monitor? What accuracy level is required? The answers to these questions will help you narrow down your options.

- Consider Your Industry Requirements: Different industries have different standards and requirements when it comes to dew point monitoring. Ensure that the monitor you choose meets or exceeds these industry-specific standards.

- Budget Constraints: Dew point monitors come at varying price points, depending on their features and technology. It’s essential to balance the need for quality and accuracy with your available budget.

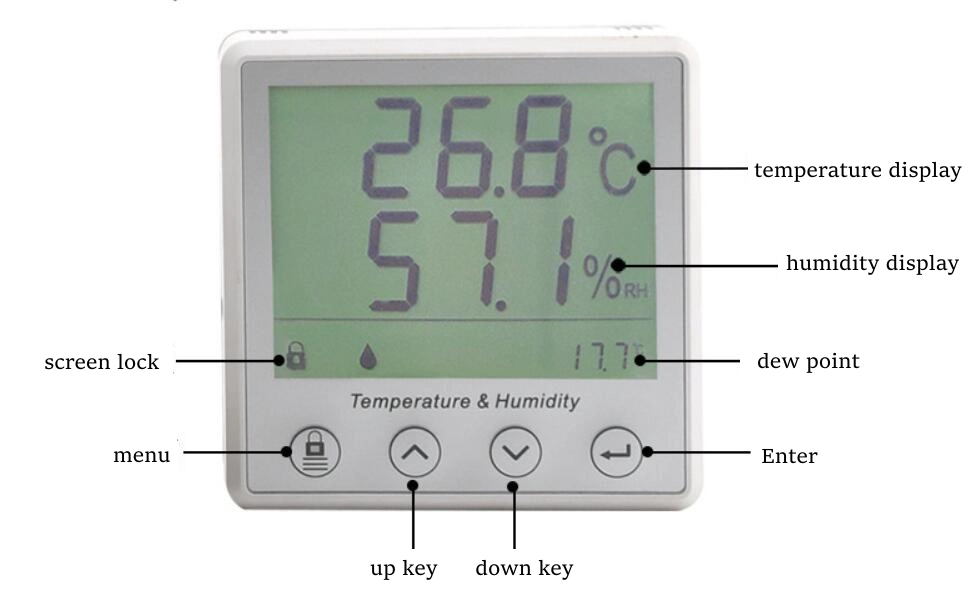

- Evaluate Features: Look for features that make the monitor easier to use and more efficient. This could include easy-to-read displays, connectivity options for remote monitoring, self-calibration features, and more.

- Research Brands and Models: There are many dew point monitor brands and models on the market. Spend some time researching and comparing them. Look at customer reviews and ratings to get a sense of their reliability and performance.

- Consider After-sales Service and Support: Good after-sales service, including technical support and warranty, can be a lifesaver if you encounter issues with the monitor.

By following these steps, you can make an informed decision and choose a dew point monitor that meets your specific needs and industry requirements, while fitting within your budget. Remember, the right dew point monitor is not just a purchase – it’s an investment in quality control and efficient operations.

More Gas Detection Sloutions

What Is Zirconia Oxygen Sensor?

Top 1 Guide to Dew Point Measurement

More than Just Compressed Air! What Gases Can the Dew Point Meter Detect?

The Role of Dew Point Meter for Compressed Air Systems

In conclusion, dew point monitors are vital instruments in a variety of industries, from HVAC and building management to pharmaceuticals, food and beverage, and beyond.

Choosing the right dew point monitor is an investment that can yield significant returns in terms of improved process control, product quality, and operational efficiency.

Sino-Inst invite you to explore our range of dew point monitors. Each of our products has been carefully designed to provide accuracy, reliability, and ease of use in mind. If you have any questions or need more personalized advice, don’t hesitate to contact us. We’re here to help you make the right choice for your specific needs and requirements.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.