what is a venturi tube?

The Venturi Tube is a tubular device commonly used to measure fluid flow rates. It is based on a physical principle, the Venturi effect. This effect states that as a fluid passes through a narrow section of a pipe, its velocity increases and its pressure decreases. The design of the Venturi Tube takes advantage of this principle, with a gradually narrowing entrance and a subsequently expanding exit. As fluid enters the narrowed portion of the venturi, it accelerates, causing the pressure to decrease. This change in pressure can be measured by pressure measuring points on the pipe wall and calculated to determine the flow rate of the fluid.

Venturi Tube is a common flow measurement tool in industry. It is widely used in the measurement of various fluids because of its simple structure, good stability and high accuracy.

Venturi Effect

The Venturi effect describes the increase in velocity and decrease in pressure as a fluid passes through a narrow section of a pipe. When fluid enters a narrow section of a pipe, the flow rate increases and the corresponding pressure decreases. This effect was discovered by Italian physicist Giovanni Battista Venturi, hence its name.

This effect can be explained by Bernoulli’s equation. This equation is a fundamental law of fluid dynamics. Show that in an incompressible fluid without viscosity, the energy of the fluid along the streamline is conserved.

P + 1/2 ρ v^2 + ρ gh = constant

P represents the pressure of the fluid

ρ is the density of the fluid

v is the velocity of the fluid

g is the acceleration due to gravity

h is the height of the fluid

In practical applications, the Venturi effect allows the venturi tube to be used to measure the velocity of a fluid in a pipe, since the velocity of the fluid is proportional to the pressure difference in the pipe.

The Venturi effect is not only used in measurement tools, but is also widely used in many fields such as aircraft wing design, chimney airflow design, and underwater piping systems. It is a very important principle in fluid mechanics and has a profound impact on many branches of engineering and physics.

Venturi tube working principle

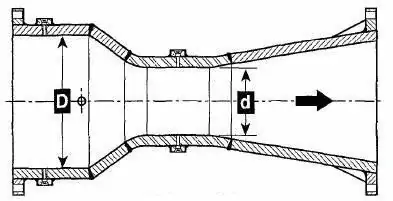

The venturi tube is composed of the following parts:

- Entrance section: a short cylindrical section with a diameter of D;

- Contracting section: the shape is a tapered tube, the cone angle is about 21°±2°;

- Throat: a short straight pipe section with a diameter of about 1/3~1/4D and a length equal to the pipe diameter;

- Diffusion section: Conical tube with a cone angle of 8°~15°. There is a pressure measuring ring at 0.25-0.75D from the end of the inlet section, with at least 4 pressure measuring holes on it, and the pressure ring leads to the pressure gauge.

In addition, in the center of the throat, there is also a multi-channel pressure measuring ring leading to the pressure gauge. The pressure difference between the inlet section and the smallest section (that is, the throat section) can be measured through the scale of the pressure gauge or the automatic recorder.

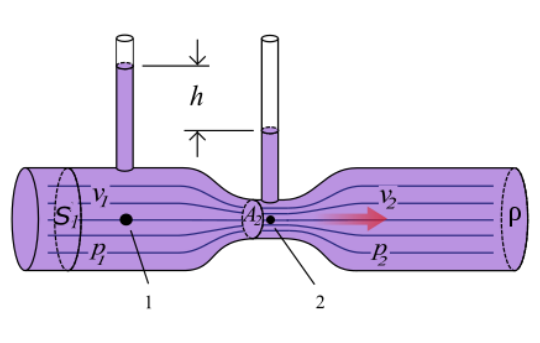

Suppose the average velocity, average pressure, and cross-sectional area at the entrance section and the throat are v1, p1, S1, and v2, p2, S2; the fluid density is ρ.

Applying Bernoulli’s theorem and the continuity equation and noting that the streamlines of average motion are of the same height, we can get:

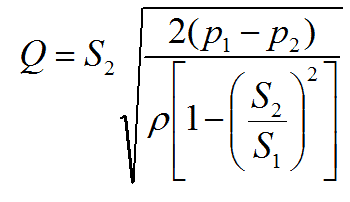

The formula for calculating the flow rate Q can be obtained:

After knowing ρ, S1, S2 and measuring p1-p2, the flow rate Q can be obtained according to the above formula.

The main advantage of the venturi tube is its simplicity of installation. Secondly, due to its diffusion section, the fluid gradually decelerates, reducing the turbulence (see turbulence). Therefore, the pressure head loss is small, no more than 10-20% of the pressure difference between the inlet and the throat.

Venturi tube design

According to the manufacturing process and use, the venturi is divided into standard venturi, general venturi, venturi flow tube, small diameter venturi, rectangular venturi, and other structures. The detailed structure is as follows:

Structure type:

The standard (classic) Venturi tube is composed of an inlet cylindrical section A, a conical contraction section B, a cylindrical throat C, and a conical diffusion section E. The diameter of the cylinder section A is D, and its length is equal to D; the contraction section B is conical and has an included angle of 21º±1º; the throat C is a circular cylinder section with a diameter d, and its length is equal to d; the divergent section E It has a conical shape with a spread angle of 7º~ 15º.

The general-purpose venturi, like the standard venturi, is composed of an inlet cylindrical section A, a conical contraction section B, a cylindrical throat C, and a conical diffusion section E.

The general-purpose venturi adopts the method of changing the contraction angle of the standard venturi and the length of the diffusion section to make it have the advantages of venturi, greatly shortening the length of the body, and effectively reducing the pressure loss.

The Venturi flow tube is also composed of an inlet cylindrical section A, a conical contraction section B, a cylindrical throat C, and a conical diffusion section E. The Venturi flow tube adopts a special pressure method to make it widely used in the flow measurement of dirty media and mixed-phase flow.

The small diameter venturi is composed of an inlet cylindrical section A, a conical contraction section B, a cylindrical throat C, and a conical diffusion section E. The small diameter venturi adopts an integrated mechanical processing method to measure the fluid flow of small diameters. At the same time, it can use a variety of materials to meet the requirements of the on-site working conditions and can meet various connection methods such as welding, flange connection, and threaded connection.

The rectangular venturi is composed of an inlet cylindrical section A, a conical contraction section B, a cylindrical throat C, and a conical diffusion section E. Main technical parameters of rectangular venturi:

- Nominal diameter: DN=1.13×(WH)0.5≤6000mm

- Inlet diameter ratio W/H: 0.5≤W/H≤2.0

- Throat diameter ratio w/h: 0.5≤w/h≤2.0

- Equivalent β value: 0.44≤β=(w/h)0.5/(W/H)0.5≤0.74

- Reynolds number range: 2×105≤ReD≤2×107

- Accuracy: ±1%

- Repeatability: ±1%

- Working pressure: 0~25Mpa

- Working temperature: -100℃~500℃

- Turndown ratio: 1:10

Rectangular venturi is mainly used in power plant air supply and suction, heating furnace air supply, and suction occasions.

Extended reading: Pitot Tube vs Venturi Meter

How does a Venturi tube measure flow?

Using the Venturi Effect to measure flow, the simple steps are as follows:

- Install the venturi: First install the venturi in the pipe where the flow is to be measured.

- Connect the differential pressure sensor:

- Install a pressure sensor at the wide end and the narrow end of the venturi tube. These sensors measure the pressure difference between the two ends, which is directly related to the fluid velocity.

- Reading the pressure difference:

- As fluid passes through a venturi, its velocity increases in the narrow section, causing the pressure there to drop. The differential pressure sensor reads the pressure values at the wide end and narrow end and calculates the pressure difference between the two.

- Calculate flow velocity:

- Use Bernoulli’s equation and continuity equation to calculate the velocity of the fluid. v = sqrt(2(P1 – P2)/ρ). where P1 is the pressure at the wide end, P2 is the pressure at the narrow end, and ρ is the density of the fluid.

- Determine the flow rate:

- Calculate the flow rate (Q), the formula is: Q = A2 × v. where A2 is the cross-sectional area of the narrow portion of the venturi tube and v is the fluid velocity calculated in the previous step.

- Recording and monitoring: Continuously monitor pressure difference and flow, and record data for analysis or monitoring system status.

Venturi tube flow meter

A Venturi flow meter is a differential pressure flowmeter. The Venturi flow meter is a combination of a Venturi tube, a differential pressure transmitter, and a valve block. It is often used to measure the flow of pressure pipes.

Venturi flow meters are often used to measure the flow of fluids such as air, natural gas, coal gas, and water. It includes three parts: “constriction”, “throat” and “diffusion”. Install on the pipe where the flow rate needs to be measured.

Venturi flowmeter is a new generation of differential pressure flow measuring instruments. The basic measurement principle is a flow measurement method based on the law of conservation of energy-Berlier equation and flows continuity equation.

The throttling process of fluid flowing through the inner venturi tube is basically similar to the throttling process of fluid flowing through a classic venturi tube and an annular orifice plate.

Extended reading: Fluid flow meter types

Venturi flow meters types:

Classic Venturi:

It is applied to the flow measurement of various media and has the characteristics of small permanent pressure loss, the required long and short front and rear straight pipe sections, and long service life.

Casing type venturi:

It is mainly used in the flow measurement and control of various large-caliber and high-pressure or dangerous media in the petrochemical industry.

Venturi nozzle:

It is suitable for the measurement occasions of various media. It has the characteristics of small permanent pressure loss, a short length of the front and rear straight pipes required, and long life. The installation length of the body is shorter than that of the classic venturi.

Extended reading: What is a flow nozzle?

Read more about: 5 Factors Affecting Pressure Drop

Venturi tube application

Since its development, venturi products have been successfully applied to the measurement of high-humidity natural gas, low-pressure dirty biogas, coke oven gas, gas, steam, hot water, high-temperature hot kerosene, etc., And the practical application range is rapidly expanding.

Besides, the venturi tube has a unique measurement advantage, for measuring conditions such as long straight pipe installation conditions, special high temperature, high pressure, strong corrosive and dirty media, and non-single phase flow measurement.

Of course, in the sewage and wastewater treatment industry, in addition to venturi flowmeters, electromagnetic flowmeters are also the first consideration for many users.

For example, if you need to measure the flow of wastewater in a 2-inch pipe. Then you can refer to Magnetic Flow Meters Guides.

Extended reading: Hot Water Flow Meters Improve Heating-Boiler System

Related blog

Related DP flowmeters

Sino-Inst offers over 50 flow meter products. About 50% of these are differential pressure flow meters (like the Orifice flowmeter), 40% are Magnetic Flow Meters, and 40% are Thermal mass flowmeters.

A wide variety of Annubar flow meter options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of flow measurement instrumentation, located in China.

The top supplying country is China (Mainland), which supply 100% of the turbine flow meter respectively. Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.