What Is Hydrostatic Pressure?

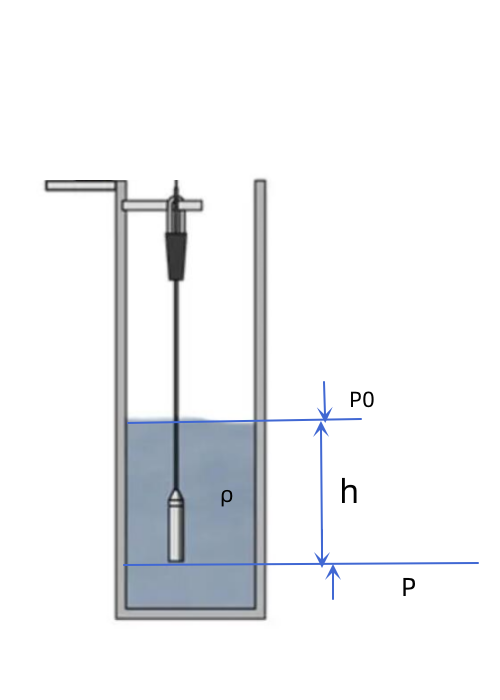

In simple terms, hydrostatic pressure refers to the pressure created by the weight of a liquid resting above a specific point. When a liquid is not in motion, the pressure it exerts at any given point is directly related to the height of the liquid column above that point, assuming the liquid has a uniform density.

The hydrostatic properties of a liquid can vary based on several factors, with the density of the liquid and local gravity being the most important. To accurately determine the hydrostatic pressure of a particular liquid, it is essential to know both of these quantities.

Importance of Hydrostatic Pressure in Industry

Hydrostatic pressure is of great significance across various industrial sectors.

Here is a list of industries and applications where hydrostatic pressure is particularly important:

- Fluid storage and transportation: Accurate hydrostatic pressure measurement is crucial for monitoring tank levels and managing liquid flow through pipelines. Helping to prevent overflows, leaks, and other issues.

- Marine engineering: Hydrostatic pressure is vital for designing and maintaining the stability of ships, submarines, and other aquatic vessels. As it influences buoyancy, ballasting, and structural design.

- Civil engineering: Projects such as dam and reservoir design require a deep understanding of hydrostatic pressure. To ensure structures can withstand the force exerted by the water they contain. It is also essential for groundwater monitoring and the construction of tunnels and underground structures.

- Environmental monitoring and remediation: Hydrostatic pressure measurements are useful in flood forecasting, water resource management, and contaminant migration analysis in groundwater. Allowing for informed decision-making and effective remediation strategies.

In short, hydrostatic pressure is a fundamental concept with far-reaching implications in various industries.

Its proper understanding and application are essential for maintaining efficiency, safety, and reliability in numerous industrial processes and systems.

Industrial Hydrostatic Pressure Measuring Instruments

Hydrostatic Level Sensor (Best Price), also called Hydrostatic level transmitter. Continuous level measurement in liquid applications with pressure sensors.

Liquid pressure sensor is widely used for pressure measurement of various liquids. Like water or oils. IP68 waterproof.

Submersible pressure transducer with 4-20mA output,

is normal submersible pressure transmitter for level measurement.

Hydrostatic level transmitter is also called hydrostatic level gauge. The rod-type Hydrostatic level transmitter 4-20mADC standard signal output. Flange or threaded installation. Can withstand high temperatures up to 450 ℃.

Stainless Steel Level Sensor-Pressure Guided Submersible Level Transmitter. The sensor part and the signal processing circuit are inside the junction box. It is used for high temperature, corrosive liquid, sewage, etc.

Submersible Level Transmitter is made of Anti-corrosive all-tetrafluoroethylene(PTFE) material. It has high temperature resistance, corrosion resistance and anti-clogging.

Well water level sensor is to apply Hydrostatic Level Sensor to deep well. Well water level sensor submerged in deep well work together with submersible water pump. Range 300m ~ 1000m.

Remote seal pressure transmitter, with capillary and diaphragm seal, remote mount. Diaphragm seal systems protect pressure transmitters from hot, viscous, contaminated or corrosive media.

Measuring Hydrostatic Pressure

Tools for converting and calculating pressure values

Applications of Hydrostatic Pressure in Industry

Hydrostatic pressure is essential in various industries, with numerous applications ranging from fluid storage to marine engineering and civil construction.

1. Tank Level Measurement

Measuring hydrostatic pressure at the bottom of a tank helps determine the liquid level inside. This information is crucial for inventory control, safety, and efficient operations. It ensures that tanks do not overflow, leak, or experience other issues. In addition to water storage tanks, it can also be used to measure the liquid level of diesel tanks.

2. Pipeline Monitoring

Hydrostatic pressure measurements are used to monitor pipelines that transport fluids like oil, gas, and water. Accurate pressure data helps prevent leaks, maintain flow rates, and detect potential issues in the pipeline system.

3. Ship Stability and Ballasting

Understanding hydrostatic pressure is vital for maintaining the stability of ships and other marine vessels. Engineers use hydrostatic pressure data to design ballast systems and ensure that ships remain stable and balanced, even under changing load conditions.

4. Submersible Vehicle Design

Hydrostatic pressure plays a key role in designing submersible vehicles, like submarines and remotely operated underwater vehicles (ROVs). Engineers must consider the pressure exerted by water at various depths to create vehicles that can withstand the harsh underwater environment.

5. Dam and Reservoir Design

In civil engineering, hydrostatic pressure is crucial for designing dams and reservoirs. These structures must be strong enough to withstand the force exerted by the water they contain. A thorough understanding of hydrostatic pressure is necessary to ensure the safety and longevity of dams and reservoirs.

6. Groundwater Monitoring

Hydrostatic pressure measurements are used to monitor groundwater levels, which is important for water resource management and environmental protection. Accurate data on groundwater pressure can help detect potential contamination, assess water availability, and inform decisions on water usage and conservation.

In summary, hydrostatic pressure has a wide range of applications across various industries, playing a critical role in ensuring efficiency, safety, and reliability in numerous industrial processes and systems.

Frequently

Asked

Questions

Related Guides

Unraveling the Pressure Puzzle: Absolute Pressure vs Gauge Pressure

Top 5 Ultrasonic Level Sensor Applications

Ultrasonic Depth Sensor vs Ultrasonic Level Sensor

How to Measure River Water Level?

How to Choose the Right Diesel Fuel Level Sensor ?

What Is Flush Diaphragm Pressure Transducer? When Use?

In conclusion, hydrostatic pressure plays a vital role in numerous industrial applications, and understanding its measurement and implications is essential for safety, efficiency, and reliability. As a leading provider of measurement solutions, Sino-Inst offers a wide range of professional hydrostatic pressure measurement transmitters to meet your specific needs.

Whether you’re involved in fluid storage, transportation, marine engineering, civil engineering, or environmental monitoring, Our Sino-Inst’s expertise and advanced products can help you achieve accurate and reliable hydrostatic pressure measurements. Don’t hesitate to contact us for more information or assistance in selecting the right solution for your application. Trust Sino-Inst to be your partner in achieving success with hydrostatic pressure management.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.