What Is Vortex Flow Meter?

A vortex flow meter is an advanced instrument designed to measure the flow velocity of fluids, both liquids,steam and gases, within a conduit or pipeline. Drawing upon the principles of fluid dynamics, it capitalizes on the formation of vortex trails, often referred to as the ‘Von Kármán Effect.’ As the fluid passes a strategically placed bluff body inside the meter, vortices are shed alternately on either side. The frequency of these shedding vortices is directly proportional to the fluid’s velocity. By capturing this frequency with sophisticated sensors, the vortex flow meter translates it into a precise flow rate. Valued for its durability and minimal pressure drop, it is a preferred choice across various industrial applications.

Featured Vortex Flow Meters

How Does Vortex Flow Meter Work?

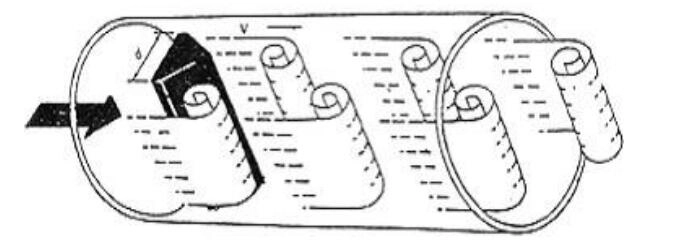

A non-streamlined vortex generating body (bluff body) is provided in the fluid. Then two rows of regular vortices are generated alternately from both sides of the vortex generator. This vortex is called a Karman vortex street. As shown below.

The vortex rows are arranged asymmetrically downstream of the vortex generator.

Suppose the frequency of vortex occurrence is f, the average velocity of the incoming flow of the measured medium is V, the width of the upstream surface of the vortex generating body is d, and the diameter of the surface body is D.

According to the Karman vortex street principle, there is the following relationship:

f=StV/d

In the formula:

F – Karman vortex frequency generated on one side of the generating body

St-Strohal number (dimensionless number)

V-average flow velocity of fluid

d-width of vortex generator

It can be seen that the instantaneous flow rate can be calculated by measuring the Karman vortex separation frequency. Among them, Strohal number (St) is a dimensionless unknown number,

The figure below shows the relationship between Strohal number (St) and Reynolds number (Re).

In the straight part of St=0.17 in the curve table, the release frequency of the wandering vortex is proportional to the flow rate, which is the measurement range of the vortex flow sensor.

As long as the frequency f is detected, the flow rate of the fluid in the pipe can be obtained. The volume flow rate can be obtained from the flow rate V. The ratio of the measured pulse number to the volume is called the instrument constant (K). See formula (2)

K=N/Q(1/m³)

In the formula:

K=instrument constant (1/m³).

N=Number of pulses

Q=Volume flow rate (m³)

Composition of vortex flowmeter

A vortex flowmeter is like a clever detective that figures out how fast a liquid or gas is moving in a pipe. Let’s break it down:

- Bluff Body: This is a small, flat piece that sticks out in the pipe. When fluid (like water or gas) flows past it, it creates little swirls or whirlpools, called vortices.

- Sensors: These are the meter’s “ears.” They listen to and count these swirls. More swirls mean the fluid is moving faster.

- Transmitter: Think of this as the meter’s “brain.” It takes the count from the sensors and works out the flow rate, or how fast the fluid is moving.

- Display: Just like a screen that shows the score in a video game, the meter has a display. It shows the flow rate so people can read it easily.

In many places, from factories to water plants, people rely on vortex flowmeters because they’re accurate and trustworthy. They help make sure everything runs smoothly and safely.

What Are Multivariable Vortex Flow Meters?

MultiVariable Vortex Meter is a product concept proposed by Rosemount.

The Rosemount™ 8800 MultiVariable Vortex Meter automatically adjusts for changes in density, making it easy to accurately measure mass and corrected volume in steam and liquid applications. No moving parts or need to install impulse lines means fewer process upsets and smoother operations for your plant.

Rosemount’s Multivariable Vortex Flow Meters certainly have their unique technical advantages. For our Sino-Inst vortex flowmeter, we provide integrated temperature and pressure compensation or split temperature and pressure compensation.

So you may ask what is temperature pressure compensation?

What is the temperature and pressure compensation of a vortex flowmeter?

Temperature and pressure compensation: Temperature and pressure compensation is the correction made by the influence of the measured object on the pressure and temperature measurement under a certain pressure and temperature. At Tongchang, we provide the most temperature and pressure compensation when measuring gas flow, which is to obtain the flow rate under standard conditions by performing temperature and pressure compensation on the gas flow under working conditions.

Flow meters for the following measurement situations require temperature or pressure compensation:

- When measuring gas, temperature and pressure need to be compensated at the same time. Gases are generally settled based on standard volume flow rates. Because the volume flow rate of the gas changes when the temperature or pressure changes, the flow rate will change.

- When measuring saturated steam, single temperature compensation or single pressure compensation is required. The density of saturated steam has a fixed corresponding relationship with temperature or pressure (saturated steam density table). Knowing any of these, the density of saturated steam can be determined.

- When measuring superheated steam, temperature and pressure need to be compensated at the same time. Steam is generally settled in terms of mass flow rate. Because either temperature or pressure changes, the density of the steam changes and the mass flow rate changes accordingly.

- When measuring liquids, pressure compensation is generally not required. Below 5MPa, generally only the influence of temperature is considered, and temperature compensation is required for accurate measurement. In general measurements, you do not need to use any compensation; when measuring some hydrocarbons (such as crude oil), simultaneous compensation of temperature and pressure is generally required.

What Are Insertion Vortex Flow Meters?

Insertion vortex flowmeters are mainly used for flow measurement of large-diameter gas, liquid, and steam media fluids in industrial pipelines in various industries. For large pipe diameters, inline installation costs can be high.

Insertion vortex flowmeters are installed by drilling a hole in the process pipe with connections. Then insert the probe into the hole through the connection on the meter. For insertion vortex flowmeters, the probe should be inserted into the part of the pipe where the flow rate is highest.

What are the Applications for Vortex Flow Meters?

- Food & Beverage: Monitoring ingredient flow during product creation.

- Factories: Monitoring liquid and gas usage in production.

- Power Plants: Measuring steam flow for electricity generation.

- Oil and Gas: Overseeing extraction and transportation processes.

- Water Treatment: Managing water flow for purification.

- Pharmaceuticals: Ensuring precise measurements for medicine production.

- Chemical Industries: Overseeing chemical reactions and product development.

- HVAC Systems: Regulating heating, ventilation, and air conditioning flows.

- Pulp & Paper Mills: Managing liquid processes in paper production.

- Agriculture: Supervising irrigation and water distribution for crops.

What Media Can Vortex Flow Meters Measure?

We all know that vortex flow meters can measure gas, steam, and liquid. Based on our many years of service experience at Sino-Inst, we have compiled some measurable media:

- Water, Chilled or Hot

- Ultra-pure Water

- De-ionized Water

- Glycol Mixtures

- Solvents & Acids

- Natural Gas

- Steam (Saturated and Superheated)

- Air and Compressed Air

- Chemicals (Various Types)

- Hydrocarbons (like oil)

This is just a small part, you are welcome to leave a comment to add more measurable media.

What are the Advantages of Vortex Flow Meters?

- All-Rounder: Measures gases, liquids, and steam effectively.

- Budget-Friendly Setup: The initial cost isn’t sky-high.

- Low Maintenance: If the media is clean, it’s mostly fuss-free.

- Trustworthy: They are reliable and give accurate readings.

- Built to Last: No moving parts means less wear and a longer life.

- Flexible Installation: Place it at any angle, just make sure the core part (bluff body) is submerged.

- Unfazed: Temperature or pressure changes? It just shrugs them off.

- No Extra Heating Needed: Unlike some meters, it doesn’t need external heat to function.

- Efficient: Generally, it doesn’t cause much pressure loss.

What are the Disadvantages and Limitations of Vortex Flow Meters?

- Picky with Thick Liquids: Not the best choice for super thick or sludgy media.

- Stay Clean: Doesn’t like media that leaves a residue or forms crystals.

- Might Need Filters: Sometimes, extra equipment like strainers are needed.

- Precision Matters: Extremely high or low flow speeds? It might falter a bit.

- Steady Flow Needed: Pulsating or jumpy flows aren’t its cup of tea.

- Space Hungry: It often asks for a long straight pipe path for best results.

- Not the Batching Type: If you’re into batching processes, it might not be the best fit.

What is the difference between vortex and mass flow meter?

Vortex flowmeters and mass flowmeters are both important flow measurement instruments. Mass flow meters have a unique point: they can measure density.

Other comparison details are as follows:

| Parameter | Vortex Flow Meter | Mass Flow Meter |

| Suitable for | Liquids, gases, steam | Almost all liquids & gases, including complex fluids |

| Not suitable for | High viscosity media, slurries | Very few; possibly some specialized applications |

| Accuracy | Inline type: ±1.5%R, Insert type: ±2.5%R, | 0.1%R 0.15%R 0.2%R 0.5%R |

| Required upstream pipe (diameters) | There are requirements for straight pipe sections. For example, there is a 15DN straight pipe section upstream and a 5DN straight pipe section downstream. | The installation requirements are not high. There are no requirements for upstream and downstream straight pipe sections. |

| Relative cost | Generally lower | Typically higher due to complexity |

| Effect of viscosity | Can impact performance; not for high viscosity | Minimal effect; can handle varying viscosities |

| Moving parts | None | Might have sensors & heaters but typically no moving parts |

| Pipe size | DN15~`DN2000 | DN3~DN200 |

| Temperature | -40℃~350℃ | -200~350℃ |

More Flow Measurement Solutions

What Is Turbine Flow Meter? and FAQs

What Is a Thermal Mass Flow Meter?

Flow Meter Straight Length Requirements Guide

What Is Density Flow Meter: Principles and Applications

What Is a Turbine Flow Meter for Gas? and Why Choose It?

The Role of Gear Flow Meters For Cement Additives

Vortex Flow Meter Manufacturers

With a rich history and dedication to innovation, Sino-Inst has become a trusted name in the flow measurement industry. Over the years, our expertise in crafting state-of-the-art vortex flow meters has solidified our position as a leader in this domain.

Sino-Inst offers a versatile range of flow meter solutions, including both inline and insertion models. For those looking beyond traditional vortex meters, we proudly present our specialized solutions tailored for unique application requirements.

Ensuring reliability and precision, our products are a testament to our commitment to engineering excellence and customer satisfaction. To explore our diverse product range and delve deeper into the world of advanced flow measurement solutions, visit the Sino-Inst product page.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.