Welcome to the world of Zirconia Oxygen Sensors, a cornerstone of precision in process control and industrial efficiency. Oxygen plays a pivotal role in numerous industrial processes, making its precise monitoring critical. That’s where our focus, the zirconia oxygen sensor, enters the scene.

What is zirconia oxygen sensor?

A zirconia oxygen sensor, also known as a zirconium dioxide oxygen sensor, is a type of sensor that measures oxygen levels, often used in automotive and industrial applications.

Its key differentiator? It relies on the unique properties of zirconia, or zirconium dioxide, a solid-state material known for its conductive abilities. But, let’s not get ahead of ourselves. By the end of this comprehensive guide, you’ll not only know how these sensors work but also appreciate their value in your operations.

Why zirconia oxygen sensor is important ?

In 1889, Nernst discovered the ionic conduction phenomenon of stabilized zirconia at high temperature. Since then, zirconia has become the most common solid electrolyte for research and development, and it has been widely used in high-temperature technology, especially high-temperature testing technology.

Compared with the existing oxygen measuring instruments (paramagnetic oxygen analyzer, electrochemical oxygen analyzer, etc.), the oxygen probe has simple structure, short response time (0.1s~0.2s), wide measurement range (from ppm to hundred content), high operating temperature (600°C ~ 1200°C), reliable operation, convenient installation, and small maintenance. Therefore, it is widely used in metallurgy, chemical industry, electric power, ceramics, automobiles, environmental protection and other industrial sectors.

In the kiln combustion process, when the air excess coefficient is too small, that is, the oxygen content is insufficient, the thermal efficiency decreases and black smoke is caused by the increase of incomplete combustion loss; when the oxygen content is too large, and due to the large exhaust smoke loss, SO2 And the amount of NOX increases. It will also lead to low thermal efficiency and environmental pollution.

Therefore, the use of the oxygen analyzer can automatically and continuously monitor the oxygen content in various furnace flue gases. To control the precise air-fuel ratio and achieve economical combustion, can obtain accurate thermal efficiency and reduce environmental pollution.

Oxygen analyzers do more than provide useful parameters for operators to adjust the air/fuel ratio. It can realize the automation of thermal control and achieve the purpose of energy saving and production increase.

The oxygen sensor, the core component of the oxygen analyzer, is made of stable zirconia material, and the melting point of the material is above 2200°C. It has good performance of high temperature resistance and corrosion resistance. Zirconia flue gas oxygen analyzer can adapt to high temperature, large dust and corrosive environment. It is unmatched by other methods, and it is the preferred instrument generally adopted by various countries in recent decades.

The Science Behind Zirconia Oxygen Sensors

1. Detection sensor

In this system, the detector is the most important working part. It directly affects the performance and life of the whole system.

Among them, the zirconium tube assembly is the main working device. It is the key to convert changes in oxygen concentration into changes in electrical signals.

The principle of oxygen measurement is as follows. The zirconium tube is mixed with yttrium oxide or calcium oxide in pure zirconium oxide. Stabilized zirconia sintered at high temperature, it is a solid electrolyte, generally made into a tube.

It is a good conductor of oxygen ions under high temperature conditions above 600°C.

Porous platinum (Pt) electrodes are sintered on both sides of the zirconia electrolyte (ZrO2 tube).

At a certain temperature, when the oxygen concentration on both sides of the electrolyte is different, the oxygen molecules on the high concentration side (air) are adsorbed on the platinum electrode and combine with electrons (4e) to form oxygen ions O2-. Make this electrode positively charged.

O2- ions migrate to the Pt electrode on the low oxygen concentration side through the oxygen ion vacancies in the electrolyte to release electrons and convert them into oxygen molecules, making the electrode negatively charged.

The zirconia tube becomes an oxygen concentration battery.

The following reaction will take place at the two platinum electrodes:

On the air side (reference side) electrode: O2+4e → 2O2-

On the hypoxic side (measured side) electrode: 2O2-→ O2+4e

That is, one oxygen molecule in the air captures four electrons on the electrode and becomes two oxygen ions. Oxygen ions migrate through zirconia to the low-oxygen side electrode driven by the potential difference in oxygen concentration. Four electrons are left to the electrode to recombine into oxygen molecules. When the battery is in equilibrium, the potential value E between the two electrodes remains constant.

Its potential value E conforms to the Nernst equation:

In the formula:

R——gas constant

T——absolute temperature

F – Faraday constant

Px——the percentage of oxygen concentration in the measured gas

Pa – the percentage of oxygen concentration in the reference gas, generally 20.60%;

In this way, if the oxygen cell is heated to a specified temperature, the measured gas and the reference gas flow through the two sides of the zirconium tube respectively, and the potential generated has a certain relationship with their concentrations. If the concentration of the reference gas is known, it is easy to determine the oxygen concentration of the measured gas.

The detector uses this principle to provide the conditions for the normal operation of the zirconium tube to achieve practical purposes.

2. Transmitter

The function of the oxygen transmitter is to convert the oxygen potential signal and temperature signal of the detector into oxygen content according to the Nernst formula, and to control the working temperature of the zirconium tube.

Summarized into temperature measurement, temperature control, oxygen conversion, output and other functions. Different kinds of transmitters are functionally identical.

Harnessing Zirconia’s Power: Industrial Applications

Industries worldwide have recognized the value of zirconia oxygen sensors. From combustion control in power plants to maintaining the optimal environment in kilns, zirconia oxygen sensors are instrumental in ensuring operations run smoothly and efficiently.

Let’s dive into some specific industrial applications where these sensors excel.

- Power Plants: Power plants, particularly those burning fossil fuels, need to closely monitor and control combustion processes to maximize efficiency and minimize emissions. Here, zirconia oxygen sensors offer an accurate and durable solution.

- Automotive Industry: Car engines use zirconia oxygen sensors (often located in the exhaust pipe) to measure the amount of oxygen in the exhaust gas. This data is crucial for the engine control unit (ECU) to adjust the air-fuel mixture and optimize engine performance.

- Food and Beverage Industry: In food packaging, zirconia oxygen sensors are used to monitor oxygen levels and ensure the longevity and quality of the product.

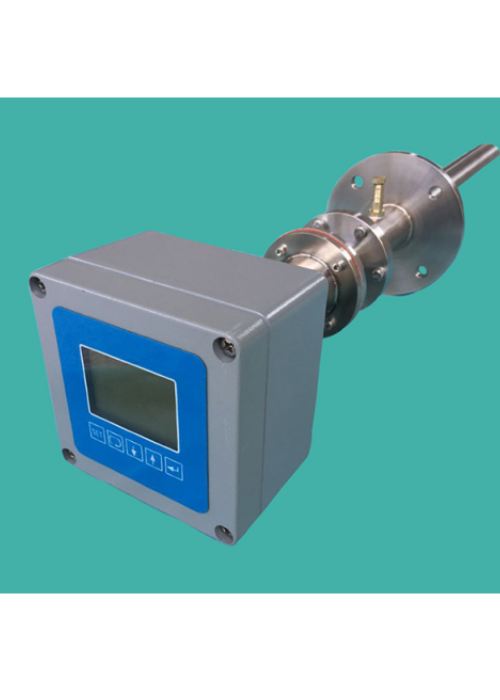

Our Recommended Zirconia Oxygen Sensors

| Display | LCD menu operation |

| Instrument accuracy | 1% |

| Temperature control accuracy | ±1℃ |

| output | 4-20mA |

| power supply | 220V+10% |

| power | <150W |

| Range | 0-25% (programmable) |

| Flue gas temperature | 0-700℃ |

| Flue gas pressure | -20KPa~+20KPa |

| Protection tube material | 316L stainless steel protection tube |

| Specification | Φ45mm |

| Transmitter material | cast aluminum |

| degree of protection | IP65 |

| flange | Outer diameter 155mm hole distance 130mm (other specifications are optional) |

| Furnace resistance value | Standard 60Ω (optional 80Ω, 120Ω, 160Ω) |

| service life | 15 years (according to actual working conditions) |

| Probe length | 500mm, 800mm, 1000mm, 1200m (other specifications can be customized) |

Selection of Zirconia Oxygen Analyzer/zirconia oxygen sensor

More Gas Measurement Solutions

Air Flow Measurement Instruments for Industrial Harsh Conditions

Measuring Steam Flow and Steam Flow Meters

What Is an Air Pressure Transducer?

Digital air flow meters

Industrial CO2 flow meters

Industrial Oxygen Flow Meters

As a seasoned manufacturer and supplier, we take pride in offering a broad range of top-tier zirconia oxygen sensors. However, we understand that every business is unique. That’s why we go above and beyond to provide customized solutions, specifically tailored to your distinct operational needs.

At Sino-Inst, we’re not just providers; we’re partners in your operational success. With our high-quality, customizable zirconia oxygen sensors, you gain accuracy, reliability, and the edge you need in your industry. Our experienced team is ready to help tailor solutions that fit your specific needs. Elevate your operations with us— reach out to Sino-Inst today. Choose excellence. Choose partnership. Choose Sino-Inst.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.