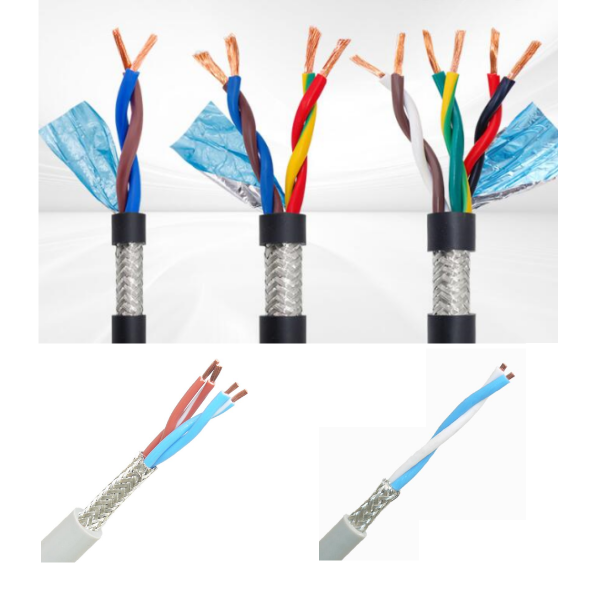

Shielded twisted pair cables (STP cables) have emerged as a preferred option for many industrial applications due to their ability to mitigate interference and deliver superior signal quality.

The communication signals we see all use shielded twisted pair cables. Shielded twisted pair cables are used like PROFIBUS. For instruments like flow meters, level meters, and pressure transmitters. Signal transmission can use Shielded twisted pair cables (STP cables ).

In daily communication, the interference of electric and magnetic fields must be shielded first. Secondly, most of them use shielded twisted pair to filter out the high frequency part of the communication signal.

The Benefits of Shielded Twisted Pair Cables in Industrial Instrumentation

- Reduced Electromagnetic Interference (EMI)

One of the primary advantages of using STP cables is their ability to minimize EMI, which can cause signal degradation and affect the performance of sensitive instrumentation. The shielding in STP cables effectively blocks external electromagnetic fields, ensuring reliable data transmission. - Enhanced Signal Quality

By reducing EMI, shielded twisted pair cables maintain superior signal quality and ensure accurate data transmission for critical industrial processes. - Increased Noise Immunity

The twisted design of STP cables, combined with their shielding, provides exceptional noise immunity, making them an ideal choice for industrial environments with high levels of electrical noise.

Reasons for Single-Ended and Double-Ended Grounding in Shielded Cables

Grounding is a crucial aspect of shielded cable installations, as it determines the effectiveness of the shield against interference signals.

Single-Ended Grounding for Shielded Cables

In ideal conditions, single-ended grounding can effectively shield against weak interference signals. However, when the interference frequency increases (e.g., above 20 kHz) or the cable length exceeds λ/20, the grounding impedance and the shield’s impedance should be considered inductive rather than resistive. As a result, the overall grounding impedance increases, and the voltage in the circuit rises with the increased interference frequency. In such cases, single-ended grounding might not be sufficient to provide adequate protection against high-frequency interference.

Double-Ended Grounding for Improved High-Frequency Interference Shielding

Double-ended grounding is designed to shield against high-frequency interference. Since most communication signals are high-frequency signals and sensitive to high-frequency interference, many communication cables employ double-ended grounding (some signals are sensitive to both high-frequency and low-frequency signals). Likewise, shielding against high-frequency magnetic field interference is achieved by forming a current loop through the shielding layer, generating a reverse magnetic field that cancels out the interfering magnetic field. Without grounding, the shielding would be ineffective!

The Importance of Equipotential Grounding

Equipotential grounding is essential for maintaining the effectiveness of the shield. If equipotential grounding is not established, ground loop currents can negatively impact the shielding performance. Therefore, before implementing double-ended grounding, equipotential bonding must be performed. It is important to note that the shielding layer should not be used as a conductor for equipotential bonding.

Understanding the reasons for single-ended and double-ended grounding in shielded cables is crucial for ensuring effective protection against interference signals, particularly in high-frequency communication systems. By selecting the appropriate grounding method based on the specific conditions and frequency ranges, you can maximize the shielding performance of your cable installations and maintain the integrity of your communication signals.

Applications of Shielded Twisted Pair Cables in Industrial Instrumentation

Product Recommendations and Customization

Shielded twisted pair cables are an invaluable asset for industrial instrumentation, providing reliable data transmission and improved process control across various industries. As an experienced manufacturer and supplier, Sino-Inst offers a wide range of industrial instrumentation products, including flow meters, level meters, and pressure transmitters. We also support customization to meet your specific requirements. Contact us today to learn more about how our solutions can help optimize your industrial processes.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.